Abstract

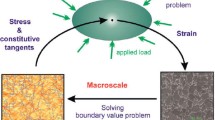

With the increased precision in laser-welded structures, smaller and thinner parts can be joined. This magnifies the effect that microstructural changes due to the welding process have on the mechanical properties of the material. Although conventional welding processes are generally applied to work pieces of larger dimensions, the higher heat inputs and longer duration of the thermal cycle can have drastic effects on the microstructure. Multiscaled models can provide a method to achieve microscopic detail in a macroscopic simulation. The dual-mesh principle proposed here places microstructure domains at the nodes of a macroscopic finite-element (FE) calculation.

Similar content being viewed by others

References

T.A. Palmer, J.W. Elmer, and J. Wong: Sci. Technol. Welding Joining, 2002, vol. 7 (3), pp. 159–71.

S.S. Babu, S. David, J.M. Vitek, and R.W. Reed: Sci. Technol. Welding Joining, 2001, vol. 6, pp. 31–40.

W. Zhang, J.W. Elmer, and T. DebRoy: Scripta Mater., 2002, vol. 46 (10), pp. 753–57.

P. Kruger: J. Phys. Chem. Solids, 1993, vol. 54 (11), pp. 1549–55.

MSC.Marc 2003 Manual Technical Report, MSC.Software Corporation, 2003.

I. Steinbach, F. Pezzolla, B. Nestler, M. See\elberg, R. Prieler, G.J. Schmitz, and J.L.L. Rezende: Physica D, 1996, vol. 94 (3), pp. 135–47.

K. Ichikawa, A. Nagomi, T. Koseki, and Y. Fukuda: Numerical Analysis of Weldability, Institute of Materials, Graz, 2001.

I. Steinbach and M. Apel: private communications, Access e.V., Aachen Germany, 2004.

M.A. Fradkin: Phys. Rev. B, 1994, vol. 50 (22), pp. 16326–39.

A. Artemev, Y. Wang, and A.G. Khachaturyan: Acta Mater., 2000, vol. 48 (10), pp. 2503–18.

A. Artemev and A.G. Khachaturyan: Shape Memory Mater., 2000, vol. 327 (3), pp. 347–50.

A.G. Khachaturyan: Theory of Structural Transformations in Solids, John Wiley & Sons, New York, NY, 1983.

E. Aa vd: Master’s Thesis, Technical University of Delft, Delft, The Netherlands, 2002.

B. Sundman, B. Jansson, and J. Andersson: “The Thermo-Calc Databank System Technical Report”, CALPHAD, Stockholm, Sweden, 1985.

J. Odqvist, B. Sandman, and J. Agren: Acta Mater., 2003, vol. 51, pp. 1035–43.

G.P. Krielaart and S. van der Zwaag: Mater. Sci. Eng. A—Struct. Mater. Prop. Microstr. Processing, 1998, vol. 246 (1–2), pp. 104–16.

S.I. Vooijs, Y. Van Leeuwen, J. Sietsma, and S. Van der Zwaag: Metall. Mater. Trans. A—Phys. Metall. Mater. Sci., 2000, vol. 31 (2), pp. 379–85.

L. Murr: Interfacial Phenomena in Metals and Alloys, Addison-Wesley, Reading, MA, 1975.

G.Y. Zhang, T. Jing, and B.C. Liu: Int. J. Cast Met. Res., 2002, vol. 15 (3), pp. 237–40.

S.S. Babu, J.W. Elmer, J.M. Vitek, and S.A. David: Acta Mater., 2002, vol. 50 (19), pp. 4763–81.

J.W. Elmer, T.A. Palmer, W. Zhang, B. Wood, and T. DebRoy: Acta Mater., 2003, vol. 51 (12), pp. 3333–49.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Thiessen, R.G., Richardson, I.M. A strategy for modeling microstructure in macroscopic simulations of welded material. Metall Mater Trans B 37, 293–299 (2006). https://doi.org/10.1007/BF02693158

Received:

Issue Date:

DOI: https://doi.org/10.1007/BF02693158