Abstract

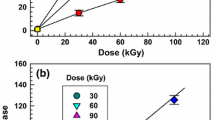

In this paper we present a methodology to measure the material traction-separation relation for a poly(ethylene carbon monoxide) copolymer, ECO. This material exhibits a ductile-to-brittle transition when subjected to ultraviolet irradiation and undergoes a change of failure mechanism, from shear yielding to crazing, in the process. Single edge notched tension specimens of ECO irradiated for 50 h were used to generate slow-speed stable crack growth, predominantly from material crazing. Full-field measurements of the in-plane deformation around the growing crack tip were performed using the optical technique of digital image correlation. A multicamera setup was used in which simultaneous measurement of both the far-field displacement and that directly surrounding the craze was performed. The far-field results were used to obtain a value of the energy release rate supplied to the crack tip region. The near-tip results were used to extract a material traction-separation law in the regime of steady-state crack growth. A softening traction-separation relation was measured. The area under the traction-separation curve was then compared with the simultaneous far-field measurements and the agreement was very good (within 6.5%) validating the experimental methodology used.

Similar content being viewed by others

Explore related subjects

Discover the latest articles and news from researchers in related subjects, suggested using machine learning.References

Xu, X.P., andNeedleman, A., “Numerical Simulations of Fast Crack Growth in Brittle Solids,”Journal of the Mechanics and Physics of Solids,42,(9),1397–1434 (1994).

Camacho, G.T. andOrtiz, M., “Computational Modeling of Impact Damage in Brittle Materials,”International Journal of Solids and Structures,33 (20–22),2899–2938 (1996).

Lin, G., Geubelle, P.H., andSottos, N.R., “Simulation of Fiber Debonding with Friction in a Model Composite Pushout Test,”International Journal of Solids and Structures,38 (46–47),8547–8562 (2001).

Barenblatt, G.I., “The Formation of Equilibrium Cracks During Brittle Fracture: General Ideas and Hypotheses, Axially Symmetric Cracks,”Applied Mathematicas and Mechanics,23,622–636 (1959).

Dugdale, D.S., “Yielding of Steel Sheets Containing Slits,”Journal of the Mechanics and Physics of Solids,8,100–108 (1960).

Kambour, R.P., “Mechanism of Fracture in Glassy Polymers. I. Fracture Surfaces in Polymethyl Methacrylate,”Journal of Polymer Science: Part A,3,1713–1724 (1965).

Kambour, R.P., “Mechanism of Fracture in Glassy Polymers. II. Survey of Crazing Response During Crack Propagation in Several Polymers,”Journal of Polymer Science: Part A-2,4,17–24 (1996).

Kambour, R.P., “Mechanism of Fracture in Glassy Polymers. III. Direct Observation of the Craze Ahead of the Propagating Crack in Poly(methyl Mechacrylate) and Polystyrene,”Journal of Polymer Science: Part A-2,4,349–358 (1966).

Beahan, P., Bevis, M., andHull, D., “Electron-microscopy Studies of Fracture Processes in Amorphous Thermoplastics,”Polymer,14 (3),96–102 (1973).

Kramer, E.J., “Microscopic and Molecular Fundamentals of Crazing,”Advances in Polymer Science,52,(3),1–56 (1983).

Yang, A.C.M., Kramer, E.J., Kuo, C.C., andPhoenix, S.L., “Craze Fibril Stability and Breakdown in Polystyrene,”Macromolecules,19 (7),2010–2019 (1986).

Berger, L.L., “On the Mechanism of Craze Fibril Breakdown in Glassy-Polymers,”Macromolecules,23 (11),2926–2934 (1990).

Hui, C.Y., Ruina, A., Creton, C., andKramer, E.J., “Micromechanics of Crack Growth into a Craze in a Polymer Glass,”Macromolecules,25,(15),3948–3955 (1992).

Tijssens, M.G.A., Van der Giessen, E., andSluys, L.J., “Modeling of Crazing Using a Cohesive Surface Methodology,”Mechanics of Materials,32 (1),19–35 (2000).

Belnap, J.D. andShetty, D.K., “Micromechanics of Crack Bridging in Sapphire/Epoxy Composites,”Composites Science and Technology,58,1763–1773 (1998).

Studer, M., Pietrzyk, J., Peters, K., Botsis, J., andGiaccari, P., “Studies on Bridging Tractions—Simultaneous Tractions and COD Measurements,”International Journal of Fracture,114,379–399 (2002).

Brown, H.R. andWard, I.M., “Craze Shape and Fracture in Poly(methyl Methacrylate),”Polymer,14,469–475 (1973).

Fraser, R.A.W. andWard, I.M., “Temperature Dependence of Craze Shape and Fracture in Polycarbonate,”Polymer,19,220–224 (1978).

Peterson, T.L., Ast, D.G., andKramer, E.J., “Holographic Interferometry of Crazes in Polycarbonate,”Journal of Applied Physics,45 (10),4220–4228 (1974).

Pandya, K.C. andWilliams, J.G., “Cohesive Zone Modeling of Crack Growth in Polymers—Part 1—Experimental Measurement of Cohesive Law,”Plastics Rubber and Composites,29 (9),439–446 (2000).

Pandya, K.C., Ivankovic, A., andWilliams, J.G., “Cohesive Zone Modeling of Crack Growth in Polymers—Part 2—Numerical Simulation of Crack Growth,”Plastics Rubber and Composites,29 (9),447–452 (2000).

Abanto-Bueno, J.L., “Fracture of a Model Functionally Graded Material Manufactured from a Photo-sensitive Polyethylene,” Ph.D. Dissertation, University of Illinois at Urbana-Champaign (2004).

Abanto-Bueno, J. andLambros, J., “Mechanical and Fracture Behavior of an Artificially Ultraviolet-irradiated Poly(ethylene carbon monoxide) Copolymer”,Journal of Applied Polymer Science,92 (1),139–148 (2004).

Domininghaus, H., Plastics for Engineers: Materials, Properties and Applications, Hanser Publishers, Munich (1993).

Patel, J., Abanto-Bueno, J., Prebil, C., and Lambros, J., “Multiscale Fracture Experiments of a Photodegradable Polyethylene Co-polymer,” SEM Conference and Exposition Proceedings, Costa Mesa, CA (2004).

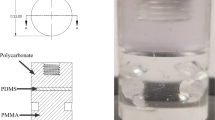

Lambros, J., Santare, M.H., Li, H., andSapna, G.H. III, “A Novel Technique for the Fabrication of Laboratory Scale Model Functionally Graded Materials,”EXPERIMENTAL MECHANICS 39 (3), 184–190 (1999).

Abanto-Bueno, J. andLambros, J., “Investigation of Crack Growth in Functionally Graded Materials Using Digital Image Correlation,”Engineering Fracture Mechanics,69 (4–16),1695–1711 (2002).

Sutton, M.A., Wolters, W.J., Peters, W.H., Ranson, W.F., andMcNeill, S.R., “Determination of Displacements Using an Improved Digital Image Correlation Method,”Image and Vision Computing,1 (3),133–139 (1983).

Bruck, H.A., McNeill, S.R., Sutton, M.A., andPeters, W.H. III. “Digital Image Correlation Using Newton-Raphson Method of Partial-differential Correction,” EXPERIMENTAL MECHANICS 29 (3), 261–267 (1989).

Vendroux, G. andKnauss, W.G., “Submicron Deformation Field Measurements: Part 2. Improved Digital Image Correlation,” EXPERIMENTAL MECHANICS 38 (2), 86–92 (1998).

Eftis, J., Subramonian, N., andLiebowitz, H., “Crack Border Stress and Displacement Equations Revisited,”Engineering Fracture Mechanics,9,189–210 (1977).

Abanto-Bueno, J. and Lambros, J., “Parameters Controlling R-curves in Functionally Graded Materials under Mode I Loading,” International Journal of Solids and Structures, submitted.

Neubrand, A., Chung, T-J., andRödel, J., “Experimental and Theoretical Investigation of R-curve Behavior in Al/Al 2O3 Functionally Graded Materials,”Materials Science Forum, 423–425, 262–274 (2003).

Estevez, R., Tijssens, M.G.A., andVan der Giessen, E., “Modeling of the Competition between Shear Yielding and Crazing in Glassy Polymers,”Journal of the Mechanics and Physics of Solids,48 (12),2585–2617 (2000).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Abanto-Bueno, J., Lambros, J. Experimental determination of cohesive failure properties of a photodegradable copolymer. Experimental Mechanics 45, 144–152 (2005). https://doi.org/10.1007/BF02428187

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02428187