Abstract

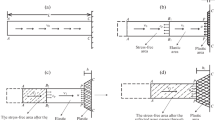

Advanced design requirements have dictated a need for the mechanical properties of materials at high strain rates. Mechanical testing for these data poses a significant problem for experimentalists. High-speed testing machines have a limited capability at rates approaching 102/s. The split Hopkinson pressure bar is the most reliable alternative for rates approaching 104/s. Plate impact experiments are capable of generating strain rates of 108/s and higher. The Taylor impact test occupies a place of particular importance by providing data at strain rates on the order of 104/s–105/s. The issue at present is extracting the data. This paper provides a method for obtaining dynamic strength model material constants from a single Taylor impact test. A polynomial response surface is used to describe the volume difference (error) between the deformed specimen from the Taylor test and the results of a computer simulation. The volume difference can be minimized using an optimizer, with the result being an optimum set of material constants. This method was applied to the modified Johnson-Cook model for OFHC copper. Starting from a nominal set of material constants, the iterative process improved the relative volume difference from 23.1 percent to 4.5 percent. Other starting points were used that yielded similar results. The material constants were validated by comparing numerical results with Taylor tests of cylinders having varying aspect ratios, calibers and impact velocities.

Similar content being viewed by others

References

Johnson, G.R., “EPIC-3, a Computer Program for Elastic-plastic Impact Calculations in 3 Dimensions,”Contract Report BRL-CR-343, Honeywell Inc., Hopkins, MN (1997).

Johnson, G.R., “Material Characterization for Warhead Computations,”Tactical Missile Warheads, ed. J. Carleone, American Institute of Aeronautics and Astronautics, Washington, DC, 165–197 (1993).

Johnson, G.R. and Cook, W.H., “A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates and High Temperatures,” Proc. 7th Int. Symp. Ballistics, The Hague, Netherlands (April 1983).

Holmquist, T.J. andJohnson, G.R., “Determination of Constants and Comparison of Results for Various Constitutive Models,”J. De Physique IV,1, C3853-C3860 (1991).

Zerilli, F.J. andArmstrong, R.W., “Dislocation-mechanics-based Constitutive Relations for Material Dynamics Calculations,”J. Appl. Phys.,61 (5),1816–1825 (1987).

Follansbee, P.S. andKocks, U.F., “A Constitutive Description of the Deformation of Copper Based on the Use of Mechanical Threshold Stress as an Internal State Variable,”Acta. Metall.,36 (1),81–93 (1988).

Taylor, G.I., “The Use of Flat-ended Projectiles for Determining Dynamic Yield Stress,”Proc. Roy. Soc. London, Series A.,194,289–299 (1948).

Lee, E.H. andTupper, S.J., “Analysis of Plastic Deformation in a Steel Cylinder Striking a Rigid Target,”J. Appl. Mech.,21,63–70 (1954).

Hawkyard, J.B., “A Theory for the Mushrooming of Flat-ended Projectiles Impinging on a Flat Rigid Anvil, Using Energy Considerations,”Int. J. Mech. Sci.,11,313–333 (1969).

Jones, S.E., Gillis, P.P., andFoster, J.C., Jr., “On the Equation of Motion of the Undeformed Section of a Taylor Impact Specimen,”J. Appl. Phys.,61,499–502, (1987).

Mauldin, P.J., Davidson, R.F. andHenninger, R.J., “Implementation and Assessment of the Mechanical-threshold-stress Model Using the EPIC2 and PINON Computer Codes,”Contract Report LA-11895-MS, Los Alamos National Laboratory, Los Alamos, NM (1990).

Hammerberg, J.E., Preston, D.L. and Wallace, D.C., “A New Model of Rate Dependent Elastic-plastic Flow,” APS 1991 Topical Conf. Shock Compression of Condensed Matter, Williamsburg, VA (1991).

Pazienza, G., Pezzica, G. and Vignolo, G.M., “Determination of the Armstrong-Zerilli Constitutive Model for AISI 316 H Stainless Steel and Application to Cylinder Impact Tests,” 7th Dymat Technical Conf., St. Louis, MO (1992).

Johnson, G.R. andHolmquist, T.J., “Evaluation of Cylinder-impact Test Data for Constitutive Model Constants,”J. Appl. Phys.,64,3901–3910 (1988).

Allen, D.J., “Use of the Taylor Impact Test to Determine Constants for Material Strength Models,”MS thesis, University of Alabama, Tuscaloosa (1995).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Allen, D.J., Rule, W.K. & Jones, S.E. Optimizing material strength constants numerically extracted from taylor impact data. Experimental Mechanics 37, 333–338 (1997). https://doi.org/10.1007/BF02317427

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02317427