Abstract

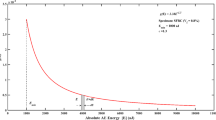

For slow crack growth (da/dn ≈0.1 µm per load cycle) in 7075-T6 aluminum, quantitative agreement was found between the amplitude distribution of burst acoustic emissions and the area size distribution of intermetallic inclusions ≈10 (µm)2 in area as measured on thepolished fracture face. This observation permits the prediction of the amplitude distribution of acoustic emissions due to crack growth in a particular sample of 7075-T6 aluminum directly from a simple, standard metallographic observation performed on the material in question. It was also found that a reduction of the yield stress from that of 7075-T6 aluminum (503 MPa) to that of 7075-0 aluminum (103 MPa) completely eliminated burst acoustic emission activity due to crack advance in the amplitude range studied.

Similar content being viewed by others

References

J. C. Spanner,Acoustic Emission—Techniques and Applications 1st ed. (Intex, Evanston, Ill., 1974), Chap. 2, p. 7.

S. H. Carpenter and C. R. Heiple, Acoustic emission generated by dislocation mechanisms during the deformation of metals, inFundamentals of Acoustic Emission K. Ono, ed., (University of California Press, Los Angeles, California, 1979), Chap. 4, pp. 49–104.

L. J. Graham, Sources of acoustic emission in aluminum alloys, inProceedings of the ARPA/ARML Review of Quantitative NDE (Science Center, Rockwell International, Thousand Oaks, Calif., 1976), pp. 631–642.

R. Bianchetti, M. A. Hamstad, and A. K. Mukherjee, Origin of burst-type acoustic emission in unflawed 7075-T6 aluminum,J. Testing Eval. 4(5):313–318 (1976).

Metals Handbook, 8th ed., Vol. 1 (American Society for Metals, Metals Park, Ohio, 1961).

K. R. Van Horn, ed.,Aluminum, Vols. 1, 2, and 3 (American Society for Metals, Metals Park, Ohio, 1967).

H. Liebowitz, ed., Fracture—an advanced treatise, inFracture of Metals, Vol. 6 (Academic Press, New York, 1969).

J. T. Staley, Microstructure and toughness of high strength Aluminum alloys, ASTM STP 605 (1976).

G. G. Garrett and J. F. Knott, The influence of compositional and microstructural variation on the mechanism of static fracture in aluminum alloys,Metallurg. Trans.,9:1187–1201 (1978).

W. F. Brown and J. E. Srawley, Plane strain crack toughness testing of high strength metallic materials, ASTM STP 410 (1966).

D. H. Harold, Acoustic emission and fatigue crack growth in 7075-T651 aluminum alloy, MSc. thesis, Royal Military College, Kingston, Ontario (1978).

B. P. Paradis, Monitoring of fatigue crack growth in 7075 aluminum alloys, MSc. thesis, Royal Military College, Kingston, Ontario (1979).

S. L. McBride and T. S. Hutchison, Absolute calibration of the helium gas jet noise source,Can. J. Phys. 56(5):504–507 (1978).

D. Broek, Particles and crack growth in aluminum alloys, inProspects of Fracture Mechanics G. C. Sih, H. C. van Elst, D. Broek, eds., (Noordhoff, Leyden, 1974), pp. 19–34.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

McBride, S.L., MacLachlan, J.W. & Paradis, B.P. Acoustic emission and inclusion fracture in 7075 aluminum alloys. J Nondestruct Eval 2, 35–41 (1981). https://doi.org/10.1007/BF00614995

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00614995