Summary

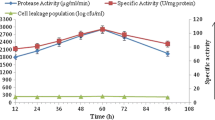

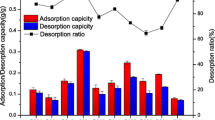

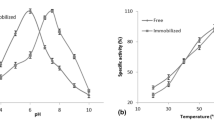

A method for the continuous production of extracellular alpha amylase by surface immobilized cells of Bacillus amyloliquefaciens NRC 2147 has been developed. A large-pore, macroreticular anionic exchange resin was capable of initially immobilizing an effective cell concentration of 17.5 g DW/1 (based on a total reactor volume of 160 ml). The reactor was operated continuously with a nutrient medium containing 15 g/l soluble starch, as well as yeast extract and salts. Aeration was achieved by sparging oxygen enriched air into the column inlet. Fermentor plugging by cells was avoided by periodically substituting the nutrient medium with medium lacking in both soluble starch and yeast extract. This fermentor was operated for over 200 h and obtained a steady state enzyme concentration of 18700 amylase activity units per litre (18.7 kU/l), and an enzyme volumetric productivity of 9700 amylase activity units per litre per hour (9.7 kU/l-h). Parallel fermentations were performed using a 2 l stirred vessel fermentor capable of operation in batch and continuous mode. All fermentation conditions employed were identical to those of the immobilized cell experiments in order to assess the performance of the immobilized cell reactor. Batch stirred tank operation yielded a maximum amylase activity of 150 kU/l and a volumetric productivity of 2.45 kU/l-h. The maximum cell concentration obtained was 5.85 g DW/l. Continuous stirred tank fermentation obtained a maximum effluent amylase activity of 6.9 kU/l and a maximum enzyme volumetric productivity of 2.73 kU/l-h. Both of these maximum values were observed at a dilution rate of 0.345 l/h. The immobilized cell reactor was observed to achieve larger volumetric productivities than either mode of stirred tank fermentation, but achieved an enzyme activity concentration lower than that of the batch stirred tank fermentor.

Similar content being viewed by others

References

Anderson E, Johansson A, Hahn-Hagerdal (1985) Alpha-amylase production in aqueous two-phase systems with Bacillus subtilis. Enzyme Microbial Technol 3:333–338

Atkinson B, Black G, Lewis P, Pinches A (1979) Biological particles of given size, shape, and density for use in biological reactors. Biotechnol Bioeng 21:193–200

Bernfield P (1955) Amylases, alpha and beta. Meth Enzymol 1:149–158

Daugulis AJ, Brown NM, Cluett WR, Dunlop BD (1981) Production of ethanol by adsorbed yeast cells. Biotechnol Lett 3:613–656

Daugulis AJ, Krug TA, Choma CET (1985) Filament formation and ethanol production by Zymomonas mobilis in adsorbed cell bioreactors. Biotechnol Bioeng 27:626–631

Forberg C, Enfors S, Haggstrom L (1983) Control of immobilized, non-growing cells for continuous production of metabolites. Eur J Appl Microbiol Biotechnol 17:143–147

Kokubu T, Karube I, Suzuki S (1978) Alpha-amylase production by immobilized whole cells of Bacillus subtilis. Eur J Appl Microbiol Biotechnol 5:233–240

Linko P, Linko Y (1983) Application of immobilized microbial cells. Appl Biochem Bioeng 4:53–151

Krug T, Daugulis AJ (1983) Ethanol production using Zymomonas mobilis immobilized on an ion exchange resin. Biotechnol Lett 5:159–164

Mattiasson B (1983) Immobilized viable cells. In: Mattiasson B (ed) CRC immobilized cells and organelles. Vol 1, CRC Press, Boca Raton, pp 23–40

Messing R, Opperman R (1979) Pore dimensions for accumulating biomass. I. Microbes that reproduce by fission or budding. Biotechnol Bioeng 21:49–58

Millar GL (1959) Use of dinitrosalicylic acid for the determination of reducing sugar. Analyt Chem 32:426–428

Morikawa Y, Karube I, Suzuki S (1980) Continuous production of bacitracin by immobilized living whole cells of Bacillus sp. Biotechnol Bioeng 22:1015–1023

Mosbach K, Birnbaum S, Hardy K, Davies J, Bulow L (1983) Formation of proinsulin by immobilized Bacillus subtilis. Nature 302:543–545

Shinmyo A, Kimura H, Okada H (1982) Physiology of Alpha-mylase production by immobilized Bacillus amyloliquefaciens. Eur J Appl Microbiol Biotechnol 14:7–12

Suzuki S, Karube I (1979) Production of antibiotics and enzymes by immobilized whole cells. In: Venkatasubramanian U (ed) Immobilized microbiol cells. American Chemical Soc., Washington D.C., pp 59–71

Venkatasubramanian K, Kakare S (1983) Process engineering considerations in the development of immobilized living cell systems. In: Mattiasson B (ed) CRC immobilized cells and organelles. Vol 1, CRC Press, Boca Raton, pp 133–144

Vieth W, Venkatasubramanian K (1979) Immobilized microbial cells in complex biocatalysis. In: Venkatasubramanian K (ed) Immobilized microbial cells. American Chemical Soc., Washington D.C., pp 1–12

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Groom, C.A., Daugulis, A.J. & White, B.N. Continuous alpha-amylase production using Bacillus amyloliquefaciens adsorbed on an ion exchange resin. Appl Microbiol Biotechnol 28, 8–13 (1988). https://doi.org/10.1007/BF00250489

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/BF00250489