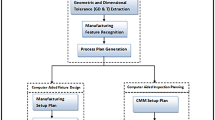

Computer-aided process planning (CAPP) is the vital link between design and manufacturing. An expert process-planning system called EPPSU has been developed to automate process planning and fixturing activities. The process planning system employs forward planning: i.e. it begins with the blank part and applies operations for each face/feature until it reaches the finished part model. After each operation the machined region is removed and a new intermediate model is generated. A part model description scheme called FONG has been utilized to represent blank, finished and intermediate models within the database. This paper explains finished part modelling within the process-planning system.

Similar content being viewed by others

References

Anderson, D. C. and Chang, T. C. (1990) Geometric reasoning in feature based design and process planning. Computers and Graphics, 14(2), 225–235.

Billo, R. E., Henderson, M. and Rucker, R. (1989) Applying conceptual graph interfacing to feature-based engineering analysis. Computers in Industry, 13, 195–214.

Bloor, M. S. and Owen, J. (1991) CAD/CAM product data exchange: the next step. Computer Aided Design, 23(4), 237–243.

Case, K. and Gaa, J. (1991) Feature technology - an overview, in Symposium on Feature Based Approaches to Design and Process Planning, Loughborough University, Loughborough, September, pp. 1–14.

Chung, J. C. H., Patel, D. R. and Cook, R. L. (1990) Feature-based modelling for mechanical design. Computers and Graphics, 14(2), 188–199.

Domazet, D. S. (1992) Concurrent design and process planning of rotational parts. Annals of the CIRP, 4(1), 181–184.

Dong, X. and Wozny, M. J. (1990) Managing feature type dependency in a feature based modelling system, in Proceedings of ASME International Computers in Engineering Conference, Boston, MA, August, 1, pp. 125–130.

Eversheim, W. (1989) Requirements on interfaces and data models for NC-data transfer in view of computer integrated manufacturing. Annals of the CIRP, 38(1), 443–446.

Gülesin, M. and Jones, R. M. (1992) An expert process planning and fixturing system with 3D CAD data input in STEP standard, in Proceedings of IMACS/SICE - The International Symposiun on Robotics, Mechatronics and Manufacturing Systems '92, Kobe, Japan, September, 2, pp. 1177–1182.

Henderson, M. R. and Chang, G. J. (1988) FRAPP: automated feature recognition and process planning from solid model data, in Proceedings of ASME, Computers in Engineering Conference, 1, pp. 529–536.

Joseph, A. T., Kalta, M. and Davies, B. J. (1990) Automatic generation of NC programs for turned components from CAD product models, in Proceedings of the 28th International MATADOR Conference, UMIST, Manchester, April, pp. 289–294.

Joshi, S. and Chang, T. C. (1988) Graph-based heuristics for recognition of machined features from a 3D solid model. Computer Aided Design, 20(2), 58–66.

Joshi, S. and Chang, T. (1990) Feature extraction and feature based design approaches in the development of design interface for process planning. Journal of Intelligent Manufacturing, 1(1), 1–15.

Kimura, F. and Suzuki, H. (1989) A CAD system for efficient product design based on design intent. Annals of the CIRP, 38(1), 149–152.

Kumar, B., Anand, D. K. and Kirk, J. A. (1988) Knowledge representation scheme for an intelligent representation scheme for an intelligent feature extractor, in Proceedings of ASME Computers in Engineering Conference, 1, pp. 543–550.

Li, J. K. and Zhang, C. (1989) Operational dimensions and tolerances calculation in CAPP systems for precision manufacturing. Annals of the CIRP, 38(1), 403–406.

Nolen, J. (1989) Computer Automated Process Planning for World-Class Manufacturing, James Nole & Company, USA.

Perng, D., Chen, Z. and Li, R. (1990) Automatic 3D machining feature extraction from 3D CSG solid input. Computer Aided Design, 22(5), 285–295.

Sakurai, H. and Gossard, D. C. (1990) Recognizing shape features in solid models. IEEE Computer Graphics & Applications, 10(8), 22–32.

Singh, R., Sittas, E., Mullineux, G. and Medland, A. J. (1990) Intelligent communications between CAD and manufacturing activities, in Proceedings of the 28th International MATADOR Conference, UMIST, Manchester, April, pp. 305–312.

Smith, B. M. (1989) Product Data Exchange: The PDES Project - Status and Objectives, NISTIR 89-4165, US Department of Commerce, NIST (National Institute of Standards and Technology), pp. 1–9.

Smith, P. (1990) CAD/CAM data exchange. CIM Review: The Journal of Computer Integrated Manufacturing Management, 6(2), 31–33.

Ssemakula, M. E. and Gill, J. S. (1989) CAD/CAPP integration using IGES. Advanced Manufacturing Engineering, 1(5), 264–270.

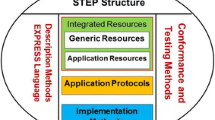

STEP (1988) First Working Draft of STEP Version 1.0, ISO TC184/SC4/WG1, 1–546.

Tilley, S. (1992) Integration of CAD/CAM and production control for sheet metal components manufacturing. Annals of the CIRP, 41(1), 177–180.

Woodwark, J. (1988) Shape models in computer integrated manufacture - a review. Computer Aided Engineering Journal, 5(6), 103–107.

Zhang, Y. and Mileham, A. R. (1991) BEPPS-NC: an automated generator of NC part programs for rotational parts from CAD product model, in Advances in Manufacturing Technology 6 - Proceedings of the Seventh National Conference on Produc- tion Research, Hatfield Polytechnic, pp. 11–15.

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gülesin, M. Finished part modelling in a computer-aided process-planning system. J Intell Manuf 7, 251–256 (1996). https://doi.org/10.1007/BF00118084

Issue Date:

DOI: https://doi.org/10.1007/BF00118084