Abstract

The discovery of Graphene as nanofiller has catalyzed a wide range of innovative areas of application. Many superior properties of graphene such as high surface area, lightweight, high mechanical strength, and high thermal conductivity as compared to other nanomaterials (layered silicates or carbon nanotubes) have garnered the attention for its application in the field of the composite. Bio-based polymers and their nanocomposites lead to very efficient interaction with the functional groups on graphene and GO due to the presence of hydroxyl, amino, or carboxyl groups in the biopolymers. Starch is the second abundant biopolymer after cellulose and has been of keen interest due to its excellent biodegradable property. Starch-biopolymers are widely used in several fields such as biomedical, pharmaceutical, food packaging, and agriculture. Incorporation of graphene into a starch biopolymer can broaden its application area by enhancing its properties. This chapter highlights the developed properties of graphene-starch nanocomposites and their fabrication techniques. It also discusses the characterization and application of graphene functionalized starch biopolymer nanocomposites (GFSBN).

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

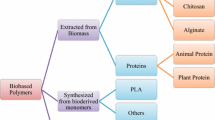

Babu RP, O’Connor K, Seeram R (2013) Current progress on bio-based polymers and their future trends. Prog. Biomater. 2(1):8

Lewitus D, McCarthy S, Ophir A, Kenig S (2006) The effect of nanoclays on the properties of PLLA-modified polymers part 1: mechanical and thermal properties. J Polym Environ 14(2):171–177

Luecha J, Sozer N, Kokini JL (2010) Synthesis and properties of corn zein/montmorillonite nanocomposite films. J Mater Sci 45(13):3529–3537

Mittal V (2008) Mechanical and gas permeation properties of compatibilized polypropylene–layered silicate nanocomposites. J Appl Polym Sci 107(2):1350–1361

Kuilla T, Bhadra S, Yao D, Kim NH, Bose S, Lee JH (2010) Recent advances in graphene based polymer composites. Prog Polym Sci 35(11):1350–1375

Soldano C, Mahmood A, Dujardin E (2010) Production, properties and potential of graphene. Carbon 48(8):2127–2150

Snook GA, Kao P, Best AS (2011) Conducting-polymer-based supercapacitor devices and electrodes. J Power Sources 196(1):1–12

Geim AK, Novoselov KS (2010) The rise of graphene. In: Nanoscience and technology: a collection of reviews from nature journals, pp 11–19

Rao CEE, Sood AE, Subrahmanyam KE, Govindaraj A (2009) Graphene: the new two-dimensional nanomaterial. Angewandte Chemie Int Edn 48(42):7752–7777

Dikin DA, Stankovich S, Zimney EJ, Piner RD, Dommett GH, Evmenenko G, Nguyen ST, Ruoff RS (2007) Preparation and characterization of graphene oxide paper. Nature 448(7152):457–460

Gadipelli S, Guo ZX (2015) Graphene-based materials: synthesis and gas sorption, storage and separation. Prog Mater Sci 69:1–60

Novoselov KS, Geim AK, Morozov S, Jiang D, Katsnelson, MI, Grigorieva I, Dubonos, SV, Firsov AA (2005) Two-dimensional gas of massless Dirac fermions in grapheme. Nature 438(7065):197–200

Stankovich S, Dikin DA, Dommett GH, Kohlhaas KM, Zimney EJ, Stach EA, Piner RD, Ngyuyen ST, Ruoff RS (2006) Graphene-based composite materials. Nature 442(7100):282–286

Araújo MA, Cunha AM, Mota M (2004) Enzymatic degradation of starch-based thermoplastic compounds used in protheses: identification of the degradation products in solution. Biomaterials 25(13):2687–2693

Teramoto N, Motoyama T, Yosomiya R, Shibata M (2003) Synthesis, thermal properties, and biodegradability of propyl-etherified starch. Eur Polymer J 39(2):255–261

Averous L (2004) Biodegradable multiphase systems based on plasticized starch: a review. Journal of Macromolecular Science Part C: Polymer Reviews 44(3):231–274

Ashori A (2014) Effects of graphene on the behavior of chitosan and starch nanocomposite films. Polym Eng Sci 54(10):2258–2263

Liu H, Xie F, Yu L, Chen L, Li L (2009) Thermal processing of starch-based polymers. Prog Polym Sci 34(12):1348–1368

Ramesh M, Mitchell JR, Jumel K, Harding SE (1999) Amylose content of rice starch. Starch-Stärke 51(8–9):311–313

Tomasik P, Schilling CH (2004) Chemical modification of starch. Adv Carbohydr Chem Biochem 59:175–403

Morrison WR, Milligan TP, Azudin MN (1984) A relationship between the amylose and lipid contents of starches from diploid cereals. J Cereal Sci 2(4):257–271

Whistler RL, BeMiller JN, Paschall EF (eds) (2012) Starch: chemistry and technology. Academic Press

Soulaka AB, Morrison WR (1985) The amylose and lipid contents, dimensions, and gelatinisation characteristics of some wheat starches and their A-and B-granule fractions. J Sci Food Agric 36(8):709–718

Lim ST, Kasemsuwan T, Jane JL (1994) Characterization of phosphorus in starch by 31P-nuclear magnetic resonance spectroscopy. Cereal Chem 71(5):488–493

Jane J, Kasemsuwan T, Chen JF, Juliano BO (1996) Phosphorus in rice and other starches. Cereal Foods World 41(11):827–832

Lii CY, Tsai ML, Tseng KH (1996) Effect of amylose content on the rheological property of rice starch. Cereal Chem 73(4):415–420

Kasemsuwan T, Jane JL (1996) Quantitative method for the survey of starch phosphate derivatives and starch phospholipids by 31P nuclear magnetic resonance spectroscopy. Cereal Chem 73(6):702–707

Kim YS, Wiesenborn DP, Orr PH, Grant LA (1995) Screening potato starch for novel properties using differential scanning calorimetry. J Food Sci 60(5):1060–1065

Leach HW, McCowen DL, Schoch TJ (1959) Swelling and solubility patterns of various starches and structure of starch granule. Cereal Chem 36:534–544

Yarahmadi E, Didehban K, Sari MG, Saeb MR, Shabanian M, Aryanasab F, Zarrinataj P, Reza Paran SM, Mozafari M, Rallini M, Puglia D (2018) Development and curing potential of epoxy/starch-functionalized graphene oxide nanocomposite coatings. Prog Org Coat 119:194–202

Lu DR, Xiao CM, Xu SJ (2009) Starch-based completely biodegradable polymer materials. Express Polym Lett 3(6):366–375

Stepto RFT (2003) The processing of starch as a thermoplastic. Macromol Symposia 201(1):203–212

Wang P, Tang S, Sheng F, Cai J, Fei P, Nawaz A, Walayat N, Javaid AB, Xiong H (2019) Crystallization, thermal stability, barrier property, and aging resistance application of multi-functionalized graphene oxide/poly (lactide)/starch nanocomposites. Int J Biol Macromol 132:1208–1220

Khan B, Niazi M, Samin G, Jahan Z (2017) Thermoplastic starch: A possible biodegradable food packaging material—A review. J Food Process Eng 40(3):e12447

Zhu F (2015) Composition, structure, physicochemical properties, and modifications of cassava starch. Carbohyd Polym 122:456–480

Jun CL (2000) Reactive blending of biodegradable polymers: PLA and starch. J Polym Environ 8(1):33–37

Mani R, Bhattacharya M (2001) Properties of injection moulded blends of starch and modified biodegradable polyesters. Eur Polymer J 37(3):515–526

Wang N, Yu J, Ma X (2008) Preparation and characterization of compatible thermoplastic dry starch/poly (lactic acid). Polym Compos 29(5):551–559

Park JW, Im SS, Kim SH, Kim YH (2000) Biodegradable polymer blends of poly (L-lactic acid) and gelatinized starch. Polym Eng Sci 40(12):2539–2550

Martin O, Avérous L (2001) Poly (lactic acid): plasticization and properties of biodegradable multiphase systems. Polymer 42(14):6209–6219

Li S, Vert M, Scott G, Gilead D (1995) Degradable polymers: principles and applications. Chapman & Hall, London, p 43

Vikman M, Hulleman SHD, Van D, Zee M, Myllärinen P, Feil H (1999) Morphology and enzymatic degradation of thermoplastic starch–polycaprolactone blends. J Appl Polym Sci 74(11):2594–2604

Dubois P, Krishnan M, Narayan R (1999) Aliphatic polyester-grafted starch-like polysaccharides by ring-opening polymerization. Polymer 40(11):3091–3100

Singh RP, Pandey JK, Rutot D, Degée P, Dubois P (2003) Biodegradation of poly (ε-caprolactone)/starch blends and composites in composting and culture environments: the effect of compatibilization on the inherent biodegradability of the host polymer. Carbohyd Res 338(17):1759–1769

Vertuccio L, Gorrasi G, Sorrentino A, Vittoria V (2009) Nano clay reinforced PCL/starch blends obtained by high energy ball milling. Carbohyd Polym 75(1):172–179

Averous L, Moro L, Dole P, Fringant C (2000) Properties of thermoplastic blends: starch–polycaprolactone. Polymer 41(11):4157–4167

Chiellini E, Corti A, D’Antone S, Solaro R (2003) Biodegradation of poly (vinyl alcohol) based materials. Prog Polym Sci 28(6):963–1014

Tudorachi N et al (2000) Testing of polyvinyl alcohol and starch mixtures as biodegradable polymeric materials. Polym Testing 19(7):785–799

Lawton JW (1996) Effect of starch type on the properties of starch containing films. Carbohyd Polym 29(3):203–208

Ke T, Sun XS (2003) Starch, poly (lactic acid), and poly (vinyl alcohol) blends. J Polym Environ 11(1):7–14

Zhai M, Zhao L, Yoshii F, Kume T (2004) Study on antibacterial starch/chitosan blend film formed under the action of irradiation. Carbohyd Polym 57(1):83–88

Bourtoom T, Chinnan MS (2008) Preparation and properties of rice starch–chitosan blend biodegradable film. LWT-Food Science and Technology 41(9):1633–1641

Cao X, Chen Y, Chang PR, Muir AD, Falk G (2008) Starch-based nanocomposites reinforced with flax cellulose nanocrystals. Express Polym Lett 2(7):502–510

Bao J, Xing J, Phillips DL, Corke H (2003) Physical properties of octenyl succinic anhydride modified rice, wheat, and potato starches. J Agric Food Chemi 51(8):2283–2287

Zheng P, Ma T, Ma X (2013) Fabrication and properties of starch-grafted graphene nanosheet/plasticized-starch composites. Ind Eng Chem Res 52(39):14201–14207

Usman A, Hussain Z, Riaz A, Khan AN (2016) Enhanced mechanical, thermal and antimicrobial properties of poly (vinyl alcohol)/graphene oxide/starch/silver nanocomposites films. Carbohyd Polym 153:592–599

Potts JR, Dreyer DR, Bielawski CW, Ruoff RS (2011) Graphene-based polymer nanocomposites. Polymer 52(1):5–25

Hu Y, Sun X (2013) Chemically functionalized graphene and their applications in electrochemical energy conversion and storage. Adv Graphene Sci 161–189

Ma J, Liu C, Li R, Wang J (2012) Properties and structural characterization of oxide starch/chitosan/graphene oxide biodegradable nanocomposites. J Appl Polym Sci 123(5):2933–2944

Li R, Liu C, Ma J (2011) Studies on the properties of graphene oxide-reinforced starch biocomposites. Carbohyd Polym 84(1):631–637

Ma T, Chang PR, Zheng P, Ma X (2013) The composites based on plasticized starch and graphene oxide/reduced graphene oxide. Carbohyd Polym 94(1):63–70

Ferreira WH, Andrade CT (2015) Characterization of glycerol-plasticized starch and graphene oxide extruded hybrids. Ind Crops Prod 77:684–690

Dilara PA, Briassoulis D (2000) Degradation and stabilization of low-density polyethylene films used as greenhouse covering materials. J Agric Eng Res 76(4):309–321

Dave AM, Mehta MH, Aminabhavi TM, Kulkarni AR, Soppimath KS (1999) A review on controlled release of nitrogen fertilizers through polymeric membrane devices. Poly-Plast Technol Eng 38(4):675–711

Guo M, Liu M, Zhan F, Wu L (2005) Preparation and properties of a slow-release membrane-encapsulated urea fertilizer with superabsorbent and moisture preservation. Ind Eng Chem Res 44(12):4206–4211

Qian C, Sun J, Yang J, Gao Y (2015) Flexible organic field-effect transistors on biodegradable cellulose paper with efficient reusable ion gel dielectrics. Rsc Adv 5(19):14567–14574

Li J, Zhao Y, Wang N, Ding Y, Guan L (2012) Enhanced performance of a MnO2–graphene sheet cathode for lithium ion batteries using sodium alginate as a binder. J Mater Chem 22(26):13002–13004

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Mishra, R., Manral, A. (2021). Graphene Functionalized Starch Biopolymer Nanocomposites: Fabrication, Characterization, and Applications. In: Sharma, B., Jain, P. (eds) Graphene Based Biopolymer Nanocomposites. Composites Science and Technology . Springer, Singapore. https://doi.org/10.1007/978-981-15-9180-8_9

Download citation

DOI: https://doi.org/10.1007/978-981-15-9180-8_9

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-9179-2

Online ISBN: 978-981-15-9180-8

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)