Abstract

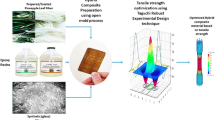

The appropriate compression molding parameters of the fabrication process of fiber reinforced polymer (FRP) composites materials are important to ensure the quality of composite samples. Therefore, this paper presents the determination of optimal compression molding parameters for pineapple leaf fiber (PLF)/polypropylene (PP) composite to get larger values of tensile strength through Taguchi method. The Taguchi’s L9 orthogonal array has been used as a design of experiment (DOE) while the tensile strength is assumed to be quality characteristic (responses). In order to determine optimal compression molding parameter, four parameters of compression molding, which were temperature, pressure, pre heat duration and compression duration have been analyzed. The nine samples of the composites were fabricated with 60 wt% fiber loading and 30 mm fiber length with random orientation. From the analysis of tensile test result, it was determined that the optimum compression molding parameters for PLF/PP composite which are 30 kg/cm2 for pressure, 175 °C for temperature, 6 and 4 min to pre heat and compression duration respectively and give the higher tensile strength of 34.57 MPa. From this result, it is concluded that the 60/40 wt% (PLF/PP) composite ratio with 30 mm fiber length that were fabricated with optimal compression molding parameters is the best combination to get high value of tensile strength. There are only slight differences between the predicted and experimental values, where the experimental tensile strength only decreased by 1.9% compared to the predicted value.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Roslan SAH, Hassan MZ, Rasid ZA, Zaki SA, Daud Y, Aziz S, Sarip S, Ismail Z (2015) Mechanical properties of bamboo reinforced epoxy sandwich structure composites. Int J Autom Mech Eng 12:2882–2892

Kengkhetkit N, Amornsakchai T (2014) A new approach to “greening” plastic composites using pineapple leaf waste for performance and cost effectiveness. Mater Des 55:292–299

Zaimy AGMK, Zafiah A, Rus M, Ab Latif N, Nurulsaidatulsyida S (2013) Mechanical and thermal properties of waste bio-polymer compound by hot compression molding technique. J Mech Eng Sci 5:582–591

Selamat MZ, Razi M, Kasim AN, Sivakumar DM, Azma P, Daud MAM, Yuhazri Y (2016) Mechanical properties of starch composite reinforced by pineapple leaf fiber (PLF) from josapine cultivar. ARPN J Eng Appl Sci 11(16):9783–9788

Kasim AN, Selamat MZ, Aznan N, Sahadan S, Daud MAM, Salleh S, Jumaidin R (2015) Effect of pineapple leaf fiber loading on the properties of pineapple leaf fiber–polypropylene composite. J Teknol 77(21):117–123

Selamat MZ, Kasim AN, Shamsudin SA, Mohd Daud MA, Dhar S (2014) Effect of bamboo fibre length on the mechanical properties of bamboo fibre/polypropylene composite. In: 8th MUCET, Melaka, Malaysia

Dhal JP, Mishra SC (2012) Processing and properties of natural fiber-reinforced polymer composite. J Mater 2013:1–6

Vinod B, Sudev L (2013) Effect of fiber orientation on the flexural properties of PALF reinforced bisphenol composites. Int J Sci Eng Appl 2:166–169

Phong NT, Fujii T, Chuong B, Okubo K (2012) Study on how to effectively extract BFs from raw bamboo and waste water treatment. Mater Sci Res 1:144–155

Abdul Khalil HPS, Bhat IUH, Jawaid M, Zaidon D, Hermawan A, Hadi YS (2012) Bamboo fiber reinforced biocomposites: a review. Mater Des 42:353–368

Raghavendra G, Acharya SK, Deo CR, Mishra P (2012) Fabrication-modelling and analysis on tribological performance of natural composites using Taguchi approach. Procedia Eng 38:2635–2644

Jeyanthi S, Janci Rani J (2012) Influence of natural long fiber in mechanical, thermal and recycling properties of thermoplastic composites in automotive components. Int J Phys Sci 7:5765–5771

Chandramohan D, Marimuthu K (2011) Tensile and hardness tests on natural fiber reinforced polymer composite material. Int J Adv Eng Sci Technol 6:97–104

Alves C, Silva A, Reis L, Freitas M, Rodrigues L (2010) Ecodesign of automotive components making use of natural jute fiber composites. J Clean Prod 18:313–327

Jawaid MHPS, Khalil HA (2011) Cellulosic/synthetic fibre reinforced polymer hybrid composites: a review. Carbohyd Polym 86(1):1–18

Mohamed AR, Sapuan SM, Khalina A (2010) Selected properties of hand-laid and compression molded vinyl ester and pineapple leaf fiber (PALF) reinforced vinyl ester composites. Int J Mech Mater Eng 5(1):68–73

Mohamed A, Sapuan S, Shahjahan M, Khalina A (2009) Characterization of pineapple leaf fibers from selected Malaysian cultivars. J Food Agric Environ 7:235–240

Kasim AN, Selamat MZ, Daud MAM, Yaakob MY, Putra A, Sivakumar D (2016) Mechanical properties of polypropylene composites reinforced with alkaline treated pineapple leaf fibre from Josapine cultivar. Int J Autom Mech Eng 13:3157–3167

Nalbant M, Gökkaya H, Sur G (2007) Application of Taguchi method in the optimization of cutting parameters for surface roughness in turning. Mater Des 28(4):1379–1385

Ghani JA, Choudhury IA, Hassan HH (2004) Application of Taguchi method in the optimization of end milling parameters. J Mater Process Technol 145(1):84–92

Montgomery DC (1997) Design and analysis of experiments, 4th edn. Wiley, New York

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15:25–33

Suherman H, Bung U (2015) Optimization of moulding parameters on the electrical conductivity of carbon black/graphite/epoxy composite for bipolar plate using the Taguchi method. Adv Mater Res 1119:201–206

Selamat MZ, Sahari J, Muchtar A, Muhamad N (2011) Simultaneous optimization for multiple responses on the compression moulding parameters of composite graphite—polypropylene using taguchi method. Key Eng Mater 471–472:361–366

Selamat MZ, Tahir MSZ, Kasim AN, Dharmalingam S, Putra A, Yaakob MY, Daud MAM (2018) Effect of starch sizes particle as binder on short pineapple leaf fiber composite mechanical properties. MATEC Web Conf 150:04008

Acknowledgements

The authors would like to thank the Malaysia Ministry of Higher Education, Malaysia Ministry of Science, Technology and Innovation for sponsoring this work under Grant FRGS/2/2014/SG06/FKM/02/F00237 and Advanced Material Research Group (A-MAT), Faculty Mechanical Engineering, University Teknikal Malaysia Melaka (UTeM) for financially sponsoring, facilities and gratefully knowledge during this research.

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2020 Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Selamat, M.Z., Kasim, A.N., Malingam, S.D., Daud, M.A.M. (2020). Optimization of Compression Molding Parameters for Pineapple Leaf Fiber Reinforced Polypropylene Composites Using Taguchi Method. In: Sabino, U., Imaduddin, F., Prabowo, A. (eds) Proceedings of the 6th International Conference and Exhibition on Sustainable Energy and Advanced Materials. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-15-4481-1_13

Download citation

DOI: https://doi.org/10.1007/978-981-15-4481-1_13

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-15-4480-4

Online ISBN: 978-981-15-4481-1

eBook Packages: EngineeringEngineering (R0)