Summary

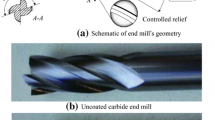

Six different TiN or TiCN coated cutters made of different substrate materials are tested under the same cutting conditions. SEM studies reveal that the tool surface after grinding of flutes prior to coating, and the thickness of the coating around the cutting edge and on the rake face are the crucial factors which determine the tool life of TiN and TiCN coated end milling cutters. The thickness of the coating on the rake face has been found to vary from almost zero to 3µm. Tests have also been conducted to establish the relationship between the rate of tool wear and th rate of change of the cutting force.

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

E. Bergmann, J. Vogel and L. Simmen (1987) Failure Mode Analysis of Coated Tools, Thin Solid Films 135, p. 219

K.G. Guenther, H. Hintermann and W. Koenig (1989) Advanced coatings by vapour phase processes, Annals of the CIRP 38/2, P. 645

S. Kaldor, P.H.H. Trendler and T. Hodgson (1984) Investigations into the clearance geometry of end mills, Annals of the CIRP 33/1, p. 33

S. Kaldor, P.H.H. Trendler and T. Hodgson (1985) Investigation and optimization of the clearance geometry of end mills, Annals of the CIRP 34/1, p. 149

W. König and K. Essel (1975) New Tool Materials, Annals of the CIRP 24/1, p. 1

W. Konig, R. Kauven and A. Droese (1986) Improved HSS tool performance with mechanically resistant coatings, Annals of the CIRP 35/1, p. 31

M.A. Mannan and B. Lindström (1986) Performance of end mills made of different tool materials with regards to tool life and stability, Annals of the CIRP 35/1, p. 37

B. Novinsek, J. Brguljan and M. Peternel (1989) Optimization of surface Morphology and tool material for TiN (PVD) Efficiency in a given Tribo-System, Mat.-wiss. u. Werkstofftech 20, p. 166

L. Westin (1989) Mechanical Properties of PM High-Speed Steels Related to Heat Treatment and Hardness, Metal Powder Report 44/11 p. 768

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Copyright information

© 1992 Department of Mechanical Engineering University of Manchester Institute of Science and Technology

About this chapter

Cite this chapter

Mannan, M.A., Westin, L., Svensson, P. (1992). Tool Life of Coated End Milling Cutters. In: Atkinson, J., Barrow, G., Burdekin, M., Chitkara, N.R., Hannam, R.G. (eds) Proceedings of the Twenty-Ninth International Matador Conference. Palgrave, London. https://doi.org/10.1007/978-1-349-12433-6_69

Download citation

DOI: https://doi.org/10.1007/978-1-349-12433-6_69

Publisher Name: Palgrave, London

Print ISBN: 978-1-349-12435-0

Online ISBN: 978-1-349-12433-6

eBook Packages: EngineeringEngineering (R0)