Abstract

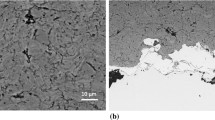

C-N films were deposited on the 20CrMo alloy steel substrate by the Plasma Source Ion Implantation (PSII) method and TiN films were coated on the same material by the Physical Vapor Deposition (PVD) method. It was found that friction coefficient of C-N coating were relatively lower than TiN coating. And with the load increased, the friction coefficients of C-N coating and TiN coating were both decreased. Then the author puts forward the test rig, working under the conditions of 1,800 rpm, 20 N·m for 100 h. The observations by microscope showed the wear reduced. The antiwearing performance enhanced prominently. But the TiN coated gear had a more serious friction phenomenon than C-N coated gear. This is caused by that coating of TiN, which was made at a high temperature about 500°C. The high temperature led to the substrate intenerated and the surface hardness had decreased from 850 HV to 630 HV. PSII method eliminates the tempering problem of the coating of C-N films, which had better wear resistance than TiN films. The friction and wear resistance of gears which coated by C-N films ameliorated significantly.

Similar content being viewed by others

References

Conrad, J. R., Dodd, A., Worzala, F. J. and Qiu, X., “Plasma Source Ion Implantation: A New, Cost-Effective, Non-Line-of- Sight Technique for Implantation of Materials,” Surface and Coatings Technology, Vol. 36, No. 3–4, pp. 927–937, 1998.

Zeng, Z. M., Kwok, T. K., Tian, X. B., Tang, B. Y. and Chu, P. K., “Plasma Immersion Ion Implantation into Inner and Outer Races of Industrial bearings,” Surface and Coatings Technology, Vol. 120–121, pp. 663–667, 1999.

Muralawa, M., Komori, T., Takeuchi, S. and Miyoshi, K., “Performance of a Rotating Gear Pair Coated with an Amorphous Carbon Film under a Loss-of-Lubrication condition,” Surface and Coatings Technology, Vol. 120–121, pp. 646–652, 1999.

Jiang, J. C., Meng, W. J., Evans, A. G. and Cooper, C. V., “Structure and Mechanics of W-DLC coated Spur Gear,” Surface and Coatings Technology, Vol. 176, pp. 50–56, 2003.

Wenfu, Q., Xingjin, C., Long, L., Nan, H., Hong, S. and Yongxiang, L., “Surface Treatment and Coating Technologies on Gears,” Journal of Chongqing University, Vol. 28, No. 2, pp. 1–4, 2005.

Hui, L., Run-fang, L., Hongbin, X. and Jin, Z., “The Analyses of Sliding-Friction Experiment of 32Cr2MoV with Different Treated Surface,” Materials Review, Vol. 20, No. 11, pp. 144–146, 2006.

Hui, L., Run-fang, L., Hongbin, X. and Jin, Z., “Analysis of Sliding-Friction Experiment of Duplex-Coated 32Cr2MoV,” Material & Heat Treatment, Vol. 35, No. 9, pp. 42–44, 2006.

Hui, L., Run-fang, L., Jin, Z. and Zhifu, S., “Structure and Friction Behaviour of Duplex-Coated 32Cr2MoV,” Material & Heat Treatment, Vol. 35, No. 2, pp. 37–39, 2006.

Hui, L., Hongbin, X., Jin, Z. and Qi, H., “Wear Behaviour of TiN Coatings on 32Cr2MoV Steel After Nitriding,” Hot Working Technology, No. 2, pp. 32–33, 2005.

Lyu, S., He, H., Lu, L. and Youn, I., “Efficiency of an SCM415 Alloy Surface Layer Implanted with Nitrogen Ions by Plasma Source Ion Implantation,” Int. J. Prec. Eng. Manuf., Vol. 7, No. 4, pp. 47–50, 2006.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lu, L., Xu, F., Jiang, T. et al. Characteristic evaluation of friction and wear in the C-N and TiN coated gear. Int. J. Precis. Eng. Manuf. 11, 107–111 (2010). https://doi.org/10.1007/s12541-010-0013-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12541-010-0013-4