Abstract

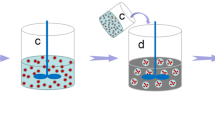

Microcapsules containing self-healing agents have been introduced into polymer to self-heal the microcracks and toughen the brittle matrix. Poly(urea–formaldehyde) (PUF) microcapsules containing epoxy resins are potential for the self-healing and toughening polymer. The resistance to medium surroundings of microcapsules is required. In the present study, PUF microcapsules containing epoxy resins were prepared by in situ polymerization. The effects of diameter, surface morphology and wall thickness on the permeability and stability of microcapsules in thermal and solvent surroundings were investigated. The morphology of microcapsule was investigated using optical microscope (OM), metalloscope (MS) and scanning electron microscope (SEM), respectively. The composition on the surface of microcapsule was analyzed by using energy dispersive analysis of X-ray (EDAX). The thermal properties of microcapsules were investigated using differential scanning calorimetry (DSC) and thermogravimetry analysis (TGA). The thermal permeability of core increases and the stability of microcapsule decreases with the enhancement of heating temperature mainly due to the expansion of epoxy resins below 251 °C and the decomposition of PUF above 251 °C. At room temperature, the permeability constants of core materials of microcapsules in acetone solvent are small and they are 1.20 × 10−3 m s−1, 1.39 × 10−3 m s−1 and 1.60 × 10−3 m s−1 corresponding to the microcapsules with diameters of 400 ± 50 μm, 230 ± 40 μm and 120 ± 30 μm. Increasing the surface smoothness, diameter and wall thickness can decrease the permeability and improve the stability of microcapsules in thermal and solvent surroundings.

Similar content being viewed by others

References

Devy J, Balasse E, Kaplan H, Madoulet C, Andry MC (2006) Int J Pharm 307:194

Povey AC, Bartsh H, O’Neill IK (1987) Cancer Lett 36:45

Alabi AO, Che Cob Z, Jones DA, Latchford JW (1999) Aquac Int 7:137

Yúfera M, Pascual E, Fernández-Díaz C (1999) Aquaculture 177:249

McMaster LD, Kokott SA, Slatter P (2005) World J Microbiol Biotechnol 21:723

Kumar A, Stephenson LD, Murray JN (2006) Prog Org Coat 55:244

Choi HJ, Lee YH, Kim CA, Jhon MS (2000) J Mater Sci Lett 19:533

Park SY, Cho MS, Kim CA, Choi HJ, Jhon MS (2003) Colloid Polym Sci 282:198

Kim KS, Lee JY, Park BJ, Sung JH, Chin I, Choi HJ, Lee JH (2006) Colloid Polym Sci 284:813

Jang IB, Sung JH, Choi HJ (2005) J Mater Sci 40:1031

White SR, Sottos NR, Geubelle PH, Moore JS, Kessler MR, Sriram SR, Brown EN, Viswanathan S (2001) Nature 409:794

Jung D, Hegeman A, Scottos NR, Geubelle PH, White SR (1997) ASME MD-80:265

Kessler MR, Sottos NR, White SR (2003) Composites: Part A 34:743

Brown EN, White SR, Sottos NR (2002) J Microencapsul 2:139

Kessler MR, White SR (2001) Composites: Part A 32:683

Brown EN, White SR, Sottos NR (2005) Compos Sci Technol 65:2474

Park SJ, Shin YS, Lee JR (2001) J Colloid Interface Sci 241:502

Guo HL, Zhao XP (2004) Opt Mater 26:297

Lee YH, Kim CA, Jang WH, Choi HJ, Jhon MS (2001) Polymer 42:8277

Lee SJ, Rosenberg M (1999) J Controll Release 61:123

Makino K, Mack EJ, Okano T, Kim SW (1990) J Controll Release 12:235

Takao M, Tetsuya T, Ichiro C (1973) BBA – Enzymology 321:653

Bryant YG (1999) ASM BED 44:225

Camino G, Operti L, Trossarelli L (1983) Polym Degrad Stab 3:161

Takamura K, Koishi M, Kondo T (1971) Polymere 248:929

Acknowledgements

The work was supported by the special research foundation of doctoral subject from the education department of high school (20050699034) and the graduate staring seed fund of Northwestern Polytechnical University (Z200584).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yuan, L., Liang, GZ., Xie, JQ. et al. The permeability and stability of microencapsulated epoxy resins. J Mater Sci 42, 4390–4397 (2007). https://doi.org/10.1007/s10853-006-0606-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-006-0606-6