Abstract

Zinc-coated advanced high-strength steels (AHSS) used in the automotive industry are vulnerable to liquid metal embrittlement (LME) during welding. In this work, a “crack index” is used to link LME crack distributions in resistance spot welds to the weld performance. Other commonly used LME metrics, such as maximum crack length, are unable to predict an effect on weld performance. Because both crack size and location have been established as critical characteristics for loss in weld strength, both of these factors must be taken into account when characterizing LME severity. The crack lengths measured in LME-affected welds were observed to fit a lognormal distribution; therefore, the lognormal median is used as the parameter to account for crack size. Long cracks are more likely to adversely impact mechanical performance. Number of cracks can be used to account for the probability that a crack will be found in a critical location. These parameters are multiplied together and divided by the sheet thickness to produce the crack index. A large crack indicates that LME cracks in the weld are likely to impact the mechanical performance of the weld. A simpler version of the crack index may be calculated using the normal median.

Similar content being viewed by others

References

Cooper AI (2015) Materials chemistry: cooperative carbon capture. Nature 519:294–295

Jakob M, Hilaire J (2015) Unburnable fossil-fuel reserves. Nature 517:150–152. https://doi.org/10.1038/517150a

McNutt M (2013) Climate change impacts. Science (80- ) 341:435. https://doi.org/10.1126/science.1243256

Creutzig F, Jochem P, Edelenbosch OY, Mattauch L, Vuuren DP, McCollum D, Minx J (2015) Transport: a roadblock to climate change mitigation? Science 350:911–912. https://doi.org/10.1126/science.aac8033

Parkes D, Xu W, Westerbaan D, Nayak SS, Zhou Y, Goodwin F, Bhole S, Chen DL (2013) Microstructure and fatigue properties of fiber laser welded dissimilar joints between high strength low alloy and dual-phase steels. Mater Des 51:665–675. https://doi.org/10.1016/j.matdes.2013.04.076

Parkes D, Westerbaan D, Nayak SS, Zhou Y, Goodwin F, Bhole S, Chen DL (2014) Tensile properties of fiber laser welded joints of high strength low alloy and dual-phase steels at warm and low temperatures. Mater Des 56:193–199. https://doi.org/10.1016/j.matdes.2013.10.087

Zhang H, Senkara J (2006) Electrothermal processes of welding. In: Resistance welding: fundamentals and applications. CRC Press, Boca Raton, pp 19–57

Ashiri R, Haque MA, Ji CW, shamanian M, Salimijazi HR, Park YD (2015) Supercritical area and critical nugget diameter for liquid metal embrittlement of Zn-coated twining induced plasticity steels. Scr Mater 109:6–10. https://doi.org/10.1016/j.scriptamat.2015.07.006

Kim YG, Kim IJ, Kim JS et al (2014) Evaluation of surface crack in resistance spot welds of Zn-coated steel. Japan Inst Met Mater 55:171–175. https://doi.org/10.2320/matertrans M2013244

Tolf E, Hedegård J, Melander A (2013) Surface breaking cracks in resistance spot welds of dual phase steels with electrogalvanised and hot dip zinc coating. Sci Technol Weld Join 18:25–31. https://doi.org/10.1179/1362171812Y.0000000068

Choi D-Y, Sharma A, Uhm S-H, Jung JP (2018) Liquid metal embrittlement of resistance spot welded 1180 TRIP steel: effect of electrode force on cracking behavior. Met Mater Int 25:219–228. https://doi.org/10.1007/s12540-018-0180-x

Barthelmie J, Schram A, Wesling V (2016) Liquid metal embrittlement in resistance spot welding and hot tensile tests of surface-refined TWIP steels. IOP Conf Ser Mater Sci Eng 118:012002. https://doi.org/10.1088/1757-899X/118/1/012002

Beal C, Kleber X, Fabregue D, Bouzekri M (2012) Embrittlement of a zinc coated high manganese TWIP steel. Mater Sci Eng A 543:76–83. https://doi.org/10.1016/j.msea.2012.02.049

Saha DC, Chang I, Park Y-D (2014) Heat-affected zone liquation crack on resistance spot welded TWIP steels. Mater Charact 93:40–51. https://doi.org/10.1016/j.matchar.2014.03.016

Gaul H, Weber G, Rethmeier M (2011) Influence of HAZ cracks on fatigue resistance of resistance spot welded joints made of advanced high strength steels. Sci Technol Weld Join 16:440–445. https://doi.org/10.1179/1362171810Y.0000000031

Benlatreche Y, Ghassemi-Armaki H, Duchet M, et al (2017) Spot-weld integrity of Zn-coated 3rd gen. Advanced high strength steels in presence of LME. Int Automot Body Congr

Jiang C, Thompson AK, Shi MF, et al (2003) Liquid metal embrittlement in resistance spot welds of AHSS steels. AWS Prof Progr

Yan B, Zhu H, Lalam S et al (2004) Spot weld fatigue of dual phase steels. SAE Tech Pap. https://doi.org/10.4271/2004-01-0511

Choi D-Y, Uhm S-H, Enloe CM et al (2017) Liquid metal embrittlement of resistance spot welded 1180TRIP steel - effects of crack geometry on weld mechanical performance. Contrib Pap from Mater Sci Technol 2017:454–462

DiGiovanni C, Biro E, Zhou N (2018) Impact of liquid metal embrittlement cracks on resistance spot weld static strength. Sci Technol Weld Join 24:1–7. https://doi.org/10.1080/13621718.2018.1518363

DiGiovanni C, Biro E, Zhou NY (2018) Effect of liquid metal embrittlement cracks on resistance spot weld fracture path. Sheet Met Weld Conf XVIII 24:218–224. https://doi.org/10.1080/13621718.2018.1518363

Ashiri R, Shamanian M, Salimijazi HR, Haque MA, Bae JH, Ji CW, Chin KG, Park YD (2016) Liquid metal embrittlement-free welds of Zn-coated twinning induced plasticity steels. Scr Mater 114:41–47. https://doi.org/10.1016/j.scriptamat.2015.11.027

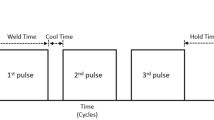

Wintjes E, Macwan A, Biro E, Zhou YN (2018) Effect of multi-pulse welding on LME severity in RSW joints. Sheet Met Weld Conf XVIII

Frei J, Rethmeier M (2018) Susceptibility of electrolytically galvanized dual-phase steel sheets to liquid metal embrittlement during resistance spot welding. Weld World 62:1031–1037. https://doi.org/10.1007/s40194-018-0619-1

American Welding Society (2012) American Welding Society: test method for evaluating the resistance spot welding behavior of automotive sheet steel materials (AWS D 89M). 1–107

Beal C (2012) Mechanical behaviour of a new automotive high manganese TWIP steel in the presence of liquid zinc [dissertation]. Insa Lyon

Taylor JR (1997) An introduction to error analysis: the study of uncertainties in physical measurements, 2nd ed. University Science Books, Sausalito, CA

Efron B (1979) Bootstrap methods: another look at the jackknife. Ann Stat 7:1–26. https://doi.org/10.1214/aos/1176344552

Acknowledgements

The authors would like to acknowledge the support of the Natural Science and Engineering Research Council of Canada and the International Zinc Association.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Recommended for publication by Commission III - Resistance Welding, Solid State Welding, and Allied Joining Process

Rights and permissions

About this article

Cite this article

Wintjes, E., DiGiovanni, C., He, L. et al. Quantifying the link between crack distribution and resistance spot weld strength reduction in liquid metal embrittlement susceptible steels. Weld World 63, 807–814 (2019). https://doi.org/10.1007/s40194-019-00712-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-019-00712-5