Abstract

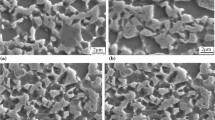

Powder metallurgy (P/M) alloy steel containing copper (Cu) and molybdenum (Mo) has tremendous potential in various industrial sectors. The present work investigates the effects of Cu and Mo addition on plastic deformation/densification characteristics of P/M plain carbon (Fe–0.5%C) steel. Sintered preforms of 1 and 2% addition of Mo and Cu to the plain carbon steel were subjected to cold upsetting by applying uni-axial load on the preforms. The compressive stress was gradually applied and increased on the alloy steel preforms till fine crack appears on lateral surface of the deformed preforms. Various analytical stresses useful for die design are evaluated using conventional plasticity correlations. The plain carbon steel is observed to exhibit better densification and deformation properties and higher strain hardening exponent value compared to other alloy steels. The basic ferrite–pearlite microstructure coupled with the presence of pore-free copper and Mo particulates is understood to influence the deformation and densification of Cu- and Mo-added alloy steels, respectively. The Cu- and Mo-added alloy steels require more axial compressive stress to attain same level of plastic deformation and densification of the plain carbon steel. Addition of Cu and Mo to the plain steel is observed to reduce the plastic flow and densification level during cold upsetting.

Similar content being viewed by others

Abbreviations

- \(P_\mathrm{l}\) :

-

Axial load

- \(\sigma _\mathrm{ex} = \sigma _z \) :

-

Axial applied or experimental stress

- \(D_{\mathrm{c}1} \) :

-

Top side contact diameter

- \(D_{\mathrm{c}2} \) :

-

Bottom side contact diameter

- \(D_\mathrm{c} \) :

-

Average contact diameter

- \(D_\mathrm{B}\) :

-

Bulge diameter

- \(D_\mathrm{O}\) :

-

Original diameter

- \(\overset{{\scriptscriptstyle \leftharpoonup }}{\sigma }_{{r_{\mathrm{b}} }} \) :

-

Apparent effective stress

- \(\delta \) :

-

Function related to density

- \(\overset{{\scriptscriptstyle \leftharpoonup }}{\sigma }_\mathrm{b}\) :

-

Yield stress

- R :

-

Relative density of compact corresponding to the yield stress

- \(R_\mathrm{c}\) :

-

Density at which the compact loses all mechanical strength and equivalent to tap density

- \(\sigma _\mathrm{eq} \) :

-

Equivalent

- B:

-

Parameter depends on relative density or Poisson’s ratio

- \(\sigma _\mathrm{th} \) :

-

Theoretical stress

- \(\upsilon \) :

-

Poison’s ratio

- \(\sigma _\mathrm{hy} \) :

-

Hydrostatic stress

- \(\overline{\varepsilon }_\mathrm{eq}\) :

-

Equivalent strain of the porous material

References

Danninger, H.; Jangg, G.; Weiss, B.; Stickler, R.: Microstructure and mechanical properties of sintered iron part I—basic considerations and review of literature. Powder Metall. Int. 25, 111–116 (1993)

Danninger, H.; Jangg, G.; Weiss, B.; Stickler, R.: Microstructure and mechanical properties of sintered iron part II—experimental study. Powder Metall. Int. 25, 170–173 (1993)

Amador, D.R.; Torralba, J.M.: Study of PM alloyed steels with Ni–Cu prealloyed powders. Int. J. Mater. Process. Technol. 143–144, 781–785 (2003)

Hwang, K.S.; Hsieh, C.H.; Shu, C.J.: Comparison of mechanical properties of Fe–1.75Ni–0.5Mo–1.5Cu–0.4C steels made from PIM and press and sinter processes. Powder Metall. 45, 160–166 (2002)

Youseffi, M.; Mitchell, S.C.; Wronski, A.S.; Cias, A.: Sintering, microstructure and mechanical properties of PM manganese–molybdenum steels. Powder Metall. 43, 353–358 (2000)

Danninger, H.; Pottschacher, R.; Bradac, S.; Salak, A.; Seyrkammer, J.: Comparison of Mn, Cr, and Mo alloyed sintered steels prepared from elemental powders. Powder Metall. 48, 23–32 (2005)

Pavier, E.; Doremus, P.: Triaxial characterisation of iron powder behaviour. Powder Metall. 42, 345–352 (1999)

Shima, S.; Oyane, M.: Plasticity theory for porous metals. Int. J. Mech. Sci. 18, 285–291 (1976)

Hwang, B.-B.; Kobayashi, S.: Deformation characterization of powdered metals in compaction. Int. J. Mech. Tools Manuf. 30, 309–323 (1990)

Narayanasamy, R.; Ponalagusamy, R.: A mathematical theory of plasticity for the upsetting of compressible P/M materials. J. Mater. Process. Technol. 97, 107–109 (2000)

Narayanasamy, R.; Ponalagusamy, R.: A mathematical theory of plasticity for compressible powder metallurgy materials—part II. J. Mater. Process. Technol. 97, 110–113 (2000)

Chandramouli, R.; Pandey, K.S.; Kandavel, T.K.; Ashokkumar, T.; Shanmughasundaram, D.: Influence of material flow constraints during cold forming on the deformation and densification behaviour of hypoeutectoid P/M steel ring preforms. Int. J. Adv. Technol. 31, 926–932 (2007)

Shanmugasundarm, D.; Chandramouli, R.; Kandavel, T.K.: Cold and hot deformation and densification studies on sintered Fe–C–Cr–Ni low alloy steels. Int. J. Adv. Technol. 41, 8–15 (2009)

Kandavel, T.K.; Chandramouli, R.; Shanmugasundaram, D.: Experimental study of the plastic deformation and densification behaviour of some sintered low alloy P/M steels. Mater. Des. 30, 1768–1776 (2009)

Kandavel, T.K.; Panneerselvam, T.; Karthikeyan, P.: Optimization of deformation and densification properties of the sintered plain carbon steel. Mater. Manuf. Process. 229(3), 487–494 (2015)

Kumar, U.J.P.; Gupta, P.; Jha, A.; Kumar, D.: Closed die deformation behaviour of cylindrical iron–alumina metal matrix composites during cold sinter forging. J. Inst. Eng. India Ser. D 97(2), 135–151 (2016)

Deng, S.; Yuan, T.; Li, R.; Zeng, F.; Liu, G.; Zhou, X.: Spark plasma sintering of pure tungsten powder: densification kinetics and grain growth. Powder Technol. 310, 264–271 (2017)

Zhou, M.; Huang, S.; Hu, J.; Lei, Y.; Zou, F.; Yan, S.; Yang, M.: Experiment and finite element analysis of compaction densification mechanism of Ag–Cu–Sn–In mixed metal powder. Powder Technol. 313, 68–81 (2017)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kandavel, T.K., Chandramouli, R. Experimental Investigations on Plastic Deformation and Densification Characteristics of P/M Fe–C–Cu–Mo Alloy Steels Under Cold Upsetting. Arab J Sci Eng 42, 4917–4927 (2017). https://doi.org/10.1007/s13369-017-2731-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-017-2731-8