Abstract

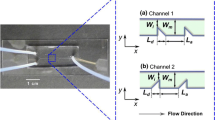

Mixing at low Reynolds number is usually due to diffusion and requires longer channel lengths for complete mixing. In order to reduce the mixing lengths, advective flow can be induced by varying the channel geometry. Additionally, in non-newtonian fluids, appropriate modifications to channel geometry can be used to aid the mixing process by capitalizing on their viscoelastic nature. Here we have exploited the advection and viscoelastic effects to implement a planar passive micro-mixer. Microfluidic devices incorporating different blend of mixing geometries were conceived. The optimum design was chosen based on the results of the numerical simulations performed in COMSOL. The chosen design had sudden expansion and contraction along with teeth patterns along the channel walls to improve mixing. Mixing of two different dyes was performed to validate the mixing efficiency. Particle dispersion experiments were also carried out. The results indicated effective mixing. In addition, the same design was also found to be compatible with electrical power free pumping mechanism like suction. The proposed design was then used to carry out on-chip chemical cell lysis with human whole blood samples to establish its use with non-newtonian fluids. Complete lysis of the erythrocytes was observed leaving behind the white blood cells at the outlet.

Similar content being viewed by others

References

Ottino, J.M. & Wiggins, S. Introduction: Mixing in microfluidics. Phil. Trans. R. Soc. Lond. A 362, 923–935 (2004).

Glasgow, I. & Aubry, N. Enhancement of microfluidic mixing using time pulsing. Lab Chip 3, 114–120 (2003).

Tsai J.-H. & Lin, L. Active microfluidic mixer and gas bubble filter driven by thermal bubble micropump. Sens. Actuators, A 97-98, 665–671 (2002).

Deval, J., Tabeling, P. & Ho, C.-M. A dielectrophoretic chaotic mixer. In The Fifteenth IEEE International Conference on Micro Electro Mechanical Systems, IEEE (2002).

Affanni, A. & Chiorboli, G. Development of an enhanced MHD micromixer based on axial flow modulation. Sens. Actuators, B 147, 748–754 (2010).

Yang, Z., Matsumoto, S., Goto, H., Matsumoto, M. & Maeda, R. Ultrasonic micromixer for microfluidic systems. Sens. Actuators, A 93, 266–272 (2001).

Kamholz, A., Weigl, B., Finlayson, B. & Yager, P. Quantitative analysis of molecular interaction in microfluidic channel: The T-sensor. Anal. Chem. 71, 5340–5347 (1999).

Ismagilov, R. et al. Experimental and theoretical scaling laws for transverse diffusive broadening in two-phase laminar flows in microchannels. Appl. Phys. Lett. 76, 2376–2378 (2000).

Kamholz, A. & Yager, P. Molecular diffusive scaling laws in pressure-driven microfluidic channels: Deviation from one-dimensional einstein approximations. Sens. Actuators, B 82, 117–121 (2002).

Nguyen, N.-T. Micromixers Fundamentals, Design and Fabrication. William Andrew Inc. (2008).

Stroock, A.D. et al. Chaotic mixer for microchannels. Science 295, 647–651 (2002).

Bessoth, F.G., deMello, A.J. & Manz, A. Microstructure for efficient continuous flow mixing. Anal. Commun. 36, 213–215 (1999).

Chen, D.L., Gerdts, C.J. & Ismagilov, R.F. Using Microfluidics to observe the effect of mixing on nucleation of protein crystals. J. Amer. Chem. Soc. 127, 9672–9673 (2005).

Song, H.J., Tice, D. & Ismagilov, R.F. A microfluidic system for controlling reaction networks in time. Angewandte Chemie International Edition 42, 768–772 (2003).

Wong, S.H., Bryant, P., Ward, M. & Wharton, C. Investigation of mixing in a cross-shaped micromixer with static mixing elements for reaction kinetics studies. Sens. Actuators, B 95, 414–424 (2003).

Wong, S.H., Ward, M.C.L. & Wharton, C.W. Micro T-mixer as a rapid mixing micromixer. Sens. Actuators, B 100, 365–385 (2004).

Gan, H., Lam, Y., Nguyen, N., Yang, C. & Tam, K. Efficient mixing of viscoelastic fluids in a microchannel at low reynolds number. Microfluid. Nanofluidics 3, 101–108 (2006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Julius, L.A.N., Jagannadh, V.K., Michael, I.J. et al. Design and validation of on-chip planar mixer based on advection and viscoelastic effects. BioChip J 10, 16–24 (2016). https://doi.org/10.1007/s13206-016-0103-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13206-016-0103-1