Abstract

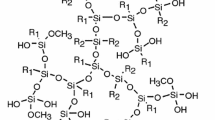

Blend samples were prepared by physical mixing of epoxy resin with varying concentration of liquid polysulfide. The blend samples were cured with aromatic acid anhydride. A comparative study of Fourier transform infrared spectra (FTIR) showed the modification as a result of chemical reaction between epoxide group, curing agent and polysulfide. The tensile strength of cured samples decreased slightly, whereas the elongation at break showed an increasing trend with increase in polysulfide content i.e. up to 50 gm. phr, in the blend samples. Appreciable improvements in impact strength were also observed in the prepared blend systems. The cured resin blend showed two phase morphology where the rubber domains were dispersed in the epoxy matrix.

Similar content being viewed by others

References

Bucknall CB, Partridge IK (1989) Polym 30:662

Pearson RA, Yee AF (1993) Polym 34:3658

Lee H, Neville H (1967) Hand Book of Epoxy Resins, McGraw Hill, New York

Hung J, Kinloch AJ (1992) J Mater Sci 27:2753

Bucknall CB (1977) Toughened Plastics, Applied Science, London

Agrawal JP, Gholap DH, Bansod VP, Satpute RS, Agawane NT (1995) Int J Eng Mater Sci 2:34–49

Agrawal JP, Satpute RS (1993) J Macromol Sci Part A 30:19–34

Agrawal JP, Satpute RS (1993) J Macromol Sci, Part A 30:19

Cranker KR, Breslau AJ (1956) Ind Eng Chem 48:34

Fettes EM, Jorczak JS (1950) Ind Eng Chem 42:2217

Guerrero P, De Caba K, Valea A, Corcuera MA, Mondragon I (1996) Polym 37:2195

Hakala K, Vatanparast R, Li SY Peinado C, Bosch P, Catalina F (2000) Macromol, 33:5954

Hardrick JL, Jurck MJ, Mcgsath I (1985) J E Eur Polym Prepr, Am Chem Soc Div Polym Chem 26:293

Gupta N, Verma IK (1998) JAPS 68:1767

Gupta N, Verma IK (1998) Angew Makromol Chem 41:367

Shechter L (1956) J Ind Eng Chem 48:94

Horne WH, Shriner RL (1956) J Am Chem Soc 54:86

Newman S, Strella S (1965) JAPS 9:2297

Barton JM (1974) J Macromol Sci Chem A8:25

kinloch AJ, Shaw SJ, Tod DA, Hunston DL (1983) Polym 24:1341

Dodiuk H, Kenig S, Liran I, Adhes J (1987) 22:284

Douglass SK, Beaumont PWR, Ashby MF (1980) J Mater Sci 15:1109

Chan LC, Gillham JK, Kinloch AJ, Shaw SJ (1984) In: Rubber-Modified Epoxies: Morphology, Transitions and Mechanical Properties. CK Riew, JK Gillham (eds.) vol. ACS208, American Chemical Society, Washington, DC pp. 274

Suer HJ, Garciameitin EI, Pickelman DM (1996) In: Polymer Toughening. CB Arands (ed.) Marcel Dekker, New York pp. 131–173

Ellis B (1993) Chemistry and technology of epoxy resins, Glasgow; Blakie Academic Professionals

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Arundhati, Singhal, R. & Nagpal, A.K. Effect of polysulfide modifier on mechanical and morphological properties of epoxy/phthalic anhydride system. Int J Plast Technol 13, 193–204 (2009). https://doi.org/10.1007/s12588-009-0015-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12588-009-0015-1