Abstract

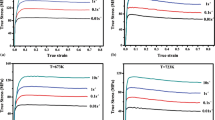

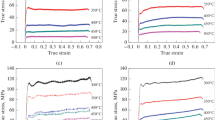

Hot deformation behavior of the 3003 Al alloy was investigated by conducting hot compression tests at various temperatures (300–500 °C) and strain rates (0.0l–10.0 s−1). A constitutive equation was established to describe the flow behavior. The apparent activation energy of the 3003 Al alloy was determined to be 174.62 kJ·mol−1, which is higher than that for self-diffusion in pure Al (165 kJ·mol−1). Processing maps at a strain of 0.6 for hot working were developed on a dynamic materials model. The maps exhibit a flow instability domain at about 300–380 °C and 1.0–10.0 s−1. Dynamic recrystallization occurs extensively in the temperature range of 450–500 °C and at the strain rate of 10.0 s−1. The optimum parameters of hot working for the 3003 Al alloy are confined at 500 °C and 10.0 s−1 with the highest efficiency (37%).

Similar content being viewed by others

References

B. Luan, T. Le, and J. Nagata, Surf. Coat. Technol. 186, 431 (2004).

A. R. Yazdzada, T. Shahrabia, and M. G. Hosseini, Mater. Chem. Phys. 109, 199 (2008).

J. Lacaze, S. Tierce, M. C. Lafont, Y. Thebault, N. Pébère, G. Mankowski, C. Blanc, H. Robidou, D. Vaumousse, D. Daloz, Mater. Sci. Eng. A 413, 317 (2005).

X. D. Huang, H. Zhanga, Y. Han, W. X. Wu, and J. H. Chen, Mater. Sci. Eng. A 527, 485 (2010).

B. H. Lee, S. M. Kim, M. E. Mehtedi, E. Evangelista, and C. S. Lee, Met. Mater. Int. 16, 197 (2010).

R. Rishi, Metall. Trans. A. 12, 1089 (1981).

H. J. Jun, K. S. Lee, C. P. Kim, and Y. W. Chang, Met. Mater. Int. 14, 297 (2008).

A. A. Omar, J. M. Cabrera, and J. M. Prado, Scr. Mater. 34, 1303 (1996).

G. S. Fu, W. Z. Chen, and K. W. Qian, The Chinese J. Nonferrous Metals. 12, 269 (2002).

G. Q. Chen, G. S. Fu, W. D. Yan, C. Z. Chen, and Z. C. Zou, J. Mater. Eng. 8, 10 (2011).

Z. Y. Liu, A. J. Duan, Y. H. Hou, S. Kang, and J. Cho, Mater. Sci. Tech. 26, 1429 (2010).

G. S. Fu, K. W. Qian, W. Z. Chen, and J. X. Kang, Trans. Nonferrous Met. Soc. China 10, 671 (2000).

A. Momeni and K. Dehghani, Met. Mater. Int. 16, 843 (2010).

Y. V. R. K. Prasad, J. Mater. Eng. Perform. 12, 638 (2003).

K. K. Pathak, V. Pagey, and N. Ramakrishnan, Mater. Sci. Tech. 26, 732 (2010).

Y. V. R. K. Prasad, T. Seshacharyulu, S. C. Medeiros, and W. G. Frazier, J. Mater. Eng. Perform. 9, 153 (2000).

Y. V. R. K. Prasad and T. Seshacharyulu, Int. Mater. Rev. 43, 243 (1998).

S. V. S. Narayana Murty, B. Nageswarra Rao, and B. P. Kashyap, Int. Mater. Rev. 45, 15 (2000).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, G., Fu, G., Chen, H. et al. Optimization of a hot deformation process of the 3003 aluminum alloy by processing maps. Met. Mater. Int. 18, 813–819 (2012). https://doi.org/10.1007/s12540-012-5010-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-012-5010-y