Abstract

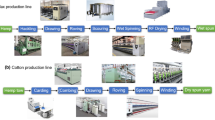

A low torque spinning method has been recently developed by integrating the ring spinning process with false twisting techniques. As a result of false twist and true twist, a novel single yarn of low torque and soft handle is generated. Based on the similar spinning principle, this paper proposed a 2-step spinning method, which is composed of twisting-anduntwisting operation and can be considered as a variant of the low torque spinning method. The proposed spinning method separates the false twisting process into twisting and untwisting processes which are combined in one step in the low torque spinning method. In this paper, physical properties of yarns produced by the proposed spinning method were evaluated and compared with the conventional yarns. Influences of various spinning parameters on the properties of 2-step yarns were also examined. Furthermore, a systematic study of the physical properties of the 2-step yarns and resultant fabrics with respect to the conventional and low torque ones was carried out. The experimental results showed that the 2-step yarns exhibit slightly higher tenacity, lower wet snarl and much less hairiness than the conventional yarns, which, however, are inferior to the low torque yarns, particularly the evenness. The fabrics made by the 2-step yarns show the softest handle feeling, best airpermeability and moderate spirality angle with acceptable pilling resistance.

Similar content being viewed by others

References

X. M. Tao and B. G. Xu, U. S. Patent, 6860095 (2005).

X. M. Tao, B. G. Xu, and S. K. Wong, U. S. Patent, 7096655 (2006).

B. G. Xu and X. M. Tao, Text. Res. J., 78, 869 (2008).

B. G. Xu, X. M. Tao, and C. S. Leung, Fiber. Polym., 11, 899 (2010).

K. Yang, X. M. Tao, B. G. Xu, and K. C. Lam, Text. Res. J., 77, 675 (2007).

Y. Guo, X. M. Tao, B. G. Xu, J. Feng, and S. Y. Wang, Text. Res. J., 81, 778 (2010).

K. Yang, Ph. D. Dissertation, The Hong Kong Polytechnic University, Hong Kong, 2006.

T. Hua, Ph. D. Dissertation, The Hong Kong Polytechnic University, Hong Kong, 2006.

J. Feng, B. G. Xu, X. M. Tao, and T. Hua, Text. Res. J., 80, 1456 (2010).

J. Feng, B. G. Xu, and X. M. Tao, Text. Res. J., 83, 238 (2013).

S. Y. Wang, “Textured Yarns”, Shanghai Scientific and Technical Publisher, Shanghai, 1992.

C. A. Lawrence, “Fundamental of Spun Yarn Technology”, Boca Raton, FL: CRC Press, 2003.

P. R. Lord, “Handbook of Yarn Production: Technology, Science and Economics”, Cambridge: Woodhead Publishing, 2003.

H. B. Tang, B. G. Xu, X. M. Tao, and J. Feng, Appl. Math. Model, 35, 139 (2011).

C. M. Murrells, K. K. Wong, X. M. Tao, and B. G. Xu, U. S. Patent, 7219556 B2 (2007).

C. M. Murrells, B. G. Xu, and X. M. Tao, Fiber. Polym., 12, 679 (2008).

C. M. Murrells, X. M. Tao, B. G. Xu, and K. P. Cheng, Text. Res. J., 79, 227 (2009).

A. Barella, Textile Progress, 13, 1 (1983).

K. P. S. Cheng and C. H. L. Li, J. Text. Inst., 72, 1079 (2002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Feng, J., Xu, B., Tao, X. et al. Performance of cotton single yarns and knitted fabrics produced by a 2-step spinning method. Fibers Polym 15, 882–890 (2014). https://doi.org/10.1007/s12221-014-0882-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-014-0882-8