Abstract

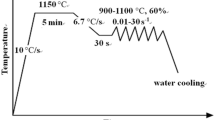

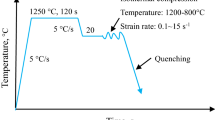

The hot compressive deformation behaviors of ZHMn34-2-2-1 manganese brass are investigated on Thermecmastor-Z thermal simulator over wide processing domain of temperatures (923–1073 K) and strain rates (0.01–10 s–1). The true stress–strain curves exhibit a single peak stress, after which the stress monotonously decreases until a steady state stress occurs, indicating a typical dynamic recrystallization. The analysis of deviation between strain-dependent Arrhenius type constitutive and experimental data revealed that the material parameters (n, A, and Q) for the ZHMn34-2-2-1 manganese brass are not constants but varies as functions of the deformation conditions. A revised strain-independent sine hyperbolic constitutive was proposed, which considered the coupled effects of strain rate temperature and strain on material parameters. The correlation coefficient and the average absolute relative error are used to evaluate the accuracy of the established constitutive model. The quantitative results indicate that the proposed constitutive model can precisely characterize the hot deformation behavior of ZHMn34-2-2-1 manganese brass.

摘要

通过Thermecmastor-Z 热模拟试验机研究了ZHMn34-2-2-1 锰黄铜在温度为923~1073 K 和应变 速率为0.01~10 s–1 的加工范围内的热压缩变形行为。真应力–应变曲线显示随着应变增加应力达到峰 值, 随后单调递减达到稳态, 表现出明显的动态再结晶行为。将建立的基于应变补偿的Arrhenius 本 构模型预测结果和实验数据进行偏差分析, 结果表明在该本构模型中, ZHMn34-2-2-1 锰黄铜材料参 数(n, A and Q)随着变形条件的波动, 不能被简单地看作一组常数。随后提出了考虑变形条件对材料参 数耦合效应补偿的改进型本构模型。利用相关系数和平均绝对相对误差对已建立本构模型的精度进行 评价, 结果表明所提出的本构模型可以准确地描述ZHMn34-2-2-1 锰黄铜的热变形特性。

Similar content being viewed by others

References

DAN W J, ZHANG W G, LI S H, LIN Z Q. A model for strain-induced martensitic transformation of TRIP steel with strain rate [J]. Computational Materials Science, 2007, 40: 101–107.

SHANG X, HE A, WANG Y, YANG X, ZHANG H, WANG X. Flow behavior modeling of a nitrogen-alloyed ultralow carbon stainless steel during hot deformation: A comparative study of constitutive models [J]. Journal of Materials Engineering and Performance, 2015, 24: 4106–4118.

LIN Y C, XIA Y C, CHEN X M, CHEN M S. Constitutive descriptions for hot compressed 2124-T851 aluminum alloy over a wide range of temperature and strain rate [J]. Computational Materials Science, 2010, 50: 227–233.

MINDIVAN H, ÇIMENOĞ LU H, KAYALI E S. Microstructures and wear properties of brass synchronizer rings [J]. Wear, 2003, 254: 532–537.

IMAI H, LI S F, KONDOH K, KOSAKA Y, OKADA T, YAMAMOTO K, AKAHASHI M, UMEDA J. Microstructure and mechanical properties of Cu-40%Zn-0.5%Cr alloy by powder metallurgy [J]. Materials Transactions, 2014, 55: 528–533.

WAHEED A, RIDLEY N. Microstructure and wear of some high-tensile brasses [J]. Journal of Materials Science, 1994, 29: 1692–1699.

CHEN Liang, ZHAO Guo, YU Jun, ZHANG Wen. Constitutive analysis of homogenized 7005 aluminum alloy at evaluated temperature for extrusion process [J]. Materials and Design, 2015, 66: 129–136.

HU Ping, SHI Dong, YING Liang, SHEN Guo, LIU Wen. The finite element analysis of ductile damage during hot stamping of 22MnB5 steel [J]. Materials and Design, 2015, 69: 141–152.

MENG Lie, WANG Meng, LIU-Xiao, WANG Feng. Hot compression deformation behavior and a modified physically-based constitutive model for Cu–6%Ag alloy [J]. Applied Physics A, 2016, 122(4): 1–11.

TRAJKOVSKI J, KUNC R, PEPEL V, PREBIL I. Flow and fracture behavior of high-strength armor steel PROTAC 500 [J]. Materials and Design, 2015, 66: 37–45.

SAMANTARAY D, MANDAL S, BHADURI A K. A comparative study on Johnson Cook, modified Zerilli–Armstrong and Arrhenius-type constitutive models to predict elevated temperature flow behaviour in modified 9Cr–1Mo steel [J]. Computational Materials Science, 2009, 47: 568–576.

LIN Yong, LI Qi, XIA Yu, LI Lei. A phenomenological constitutive model for high temperature flow stress prediction of Al–Cu–Mg alloy [J]. Materials Science and Engineering A, 2012, 534: 654–662.

LIN Yong, CHEN Xiao. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working [J]. Materials and Design, 2011, 32: 1733–1759.

SELLARS C M, TEGART W J. On the mechanism of hot deformation [J]. Acta Metallurgica, 1966, 14: 1136–1138.

JONAS J J, SELLARS C M, TEGART W J. Strength and structure under hot working conditions [J]. International Materials Reviews, 1969, 14: 1–9.

SLOOFF F A, ZHOU J, DUSZCZYK J, KATGERMAN L. Constitutive analysis of wrought magnesium alloy Mg–Al4–Zn1 [J]. Scripta Materialia, 2007, 57: 759–762.

LIN Y C, CHEN Min, ZHONG Jue. Constitutive modeling for elevated temperature flow behavior of 42CrMo steel [J]. Computational Materials Science, 2008, 42: 470–477.

SAMANTARAY D, MANDAL S, BHADURI A K. Constitutive analysis to predict high-temperature flow stress in modified 9Cr–1Mo (P91) steel [J]. Materials and Design, 2010, 31: 981–984.

CHANGIZIAN P, ZAREI-HANZAKI A, ROOSTAEI A A. The high temperature flow behavior modeling of AZ81 magnesium alloy considering strain effects [J]. Materials and Design, 2012, 39: 384–389.

CAI Zhi, CHEN Fu, GUO Jun. Constitutive model for elevated temperature flow stress of AZ41M magnesium alloy considering the compensation of strain [J]. Journal of Alloys and Compounds, 2015, 648: 215–222.

CICCARELLI D, ELMEHTEDI M, JÄGER A, SPIGARELLI S. Analysis of flow stress and deformation mechanism under hot working of ZK60 magnesium alloy by a new strain-dependent constitutive equation [J]. Journal of Physics and Chemistry of Solids, 2015, 87: 183–195.

TRIMBLE D, O’ DONNELL G E. Constitutive Modelling for elevated temperature flow behaviour of AA7075 [J]. Materials and Design, 2015, 76: 150–168.

LI Jun, XIE Zhi, LI Song, ZANG Yan. Modeling on dynamic recrystallization of aluminum alloy 7050 during hot compression based on cellular automation [J]. Journal of Central South University, 2016, 23: 497–507.

SHI Cang, CHEN X.-GRANT. Evolution of activation energies for hot deformation of 7150 aluminum alloys with various Zr and V additions [J]. Materials Science and Engineering A, 2016, 650: 197–209.

PENG X, GUO H, SHI Z, QIN C, ZHAO Z. Constitutive equations for high temperature flow stress of TC4-DT alloy incorporating strain, strain rate and temperature [J]. Materials and Design, 2013, 50: 198–206.

CAI Jun, LI Fu, LIU Tai, CHEN Bo, HE Min. Constitutive equations for elevated temperature flow stress of Ti–6Al–4V alloy considering the effect of strain [J]. Materials and Design, 2011, 32: 1144–1151.

XIAO Yan, GUO Cheng, GUO Xiao. Constitutive modeling of hot deformation behavior of H62 brass [J]. Materials Science and Engineering A, 2011, 528: 6510–6518.

KHAMEI A A, DEHGHANI K. Modeling the hotdeformation behavior of Ni60wt%–Ti40wt% intermetallic alloy [J]. Journal of Alloys and Compounds, 2010, 490: 377–381.

WANG Zhen, QI Le, ZHOU Ji, GUAN Jun, LIU Jian. A constitutive model for predicting flow stress of Al18B4O33w/AZ91D composite during hot compression and its validation [J]. Computational Materials Science, 2011, 50: 2422–2426.

AHAMED H, SENTHILKUMAR V. Hot deformation behavior of mechanically alloyed Al6063/0.75Al2O3/0.75Y2O3 nano-composite—A study using constitutive modeling and processing map [J]. Materials Science and Engineering A, 2012, 539: 349–359.

LIN Yong, WU Xian, CHEN Xiao, CHEN Jian, WEN Dong, ZHANG Jin, LI Lei. EBSD study of a hot deformed nickel-based superalloy [J]. Journal of Alloys and Compounds, 2015, 640: 101–113.

LIN Y C, HE Dao, CHEN Ming, CHEN Xiao, ZHAO Chun, MA Xiang, LONG Zhi. EBSD analysis of evolution of dynamic recrystallization grains and δ phase in a nickel-based superalloy during hot compressive deformation [J]. Materials and Design, 2016, 97: 13–24.

MARANDI A, ZAREI-HANZAKI A, HAGDADI N, ESKANDARI M. The prediction of hot deformation behavior in Fe-21Mn-2.5Si-1.5Al transformation-twinning induced plasticity steel [J]. Materials Science and Engineering A, 2012, 554: 72–78.

QUAN Guo, ZHAO Lei, CHEN Tao, WANG Yang, MAO Yuan, LV Wen, ZHOU Jie. Identification for the optimal working parameters of as-extruded 42CrMo high-strength steel from a large range of strain, strain rate and temperature [J]. Materials Science and Engineering A, 2012, 538: 364–373.

LIN Y C, NONG Fu, CHEN Xiao, CHEN Dong, CHEN Ming. Microstructural evolution and constitutive models to predict hot deformation behaviors of a nickel-based superalloy [J]. Vacuum, 2017, 137: 104–114.

QUAN Guo, TONG Ying, LUO Gang, ZHOU Jie. A characterization for the flow behavior of 42CrMo steel [J]. Computational Materials Science, 2010, 50: 167–171.

GHAEI A, MOVAHHEDY MR,KARIMI TAHERI A. Finite element modelling simulation of radial forging of tubes without mandrel [J]. Materials and Design, 2008, 29: 867–872.

WANG L, LIU F, CHENG J J, ZOU Q, CHEN C F. Arrhenius-Type constitutive model for high temperature flow stress in a nickel-based corrosion-resistant alloy [J]. Journal of Materials Engineering and Performance, 2016, 25(4): 1394–1406.

SHI Cang-ji, MAO Wei, CHEN X.-GRANT. Evolution of activation energy during hot deformation of AA7150 aluminum alloy [J]. Materials Science and Engineering A, 2013, 571: 83–91.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2012ZX04010-081) supported by the National Science and Technology Major Project of the Ministry of Science and Technology of China

Rights and permissions

About this article

Cite this article

Wang, Mh., Wei, K., Li, Xj. et al. Constitutive modeling for high temperature flow behavior of a high-strength manganese brass. J. Cent. South Univ. 25, 1560–1572 (2018). https://doi.org/10.1007/s11771-018-3848-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-018-3848-y