Abstract

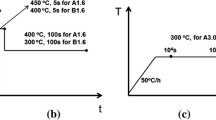

The effect of pre-recovery on the recrystallization kinetics of a supersaturated Al-Mn alloy annealed at 530 °C was investigated. The results show that the pre-recovery treatment can lead to faster recrystallization kinetics at the initial stage but cause sluggish recrystallization at the later stage. This different recrystallization behavior is explained by the formation of precipitates-free zones and the consumption of driving force during the pre-recovery treatment. The promoted recrystallization at the early stage can be interpreted by the promotion of recrystallization nucleation through sub-grain growth to a critical size inside precipitates-free zones. A simple model is presented to describe the nucleation of recrystallization with pre-recovery treatment in the supersaturated Al-Mn alloys.

摘要

研究预回复处理对Al-Mn 合金再结晶动力学的影响。研究结果表明,预回复过程中在初生相 或晶界附近形成2–3 μm 无析出带,该区域内的亚晶容易长大成为有效的再结晶核心,提高再结晶形 核率;同时,预回复消耗形变储能,并在晶粒内部析出大量的细小颗粒状Al12(Fe,Mn)3Si 相和针状Al6Mn 相,降低晶粒长大的净驱动力,减缓了晶粒长大速度。因此,在450 °C 预回复处理状态下,在530 °C 退火时形核率提高导致早期的再结晶动力学相对较快,而晶粒长大速度减缓导致晚期的再结晶动力学 相对较慢。

Similar content being viewed by others

References

HUMPHREYS F J, HATHERLY M. Recrystallization and related annealing phenomena [M]. Oxford: Elsevier, 2004.

OYARZABAL M, MARTINEZ-DE-GUERENU A, GUTIERREZ I. Effect of stored energy and recovery on the overall recrystallization kinetics of a cold rolled low carbon steel [J]. Mater Sci Eng A, 2008, 485: 200–209.

STUWE H P, PADILHA A F, SICILIANO F Jr. Competition between recovery and recrystallization [J]. Mater Sci Eng A, 2002, 333: 361–367.

DECREUS B, ZUROB H S, DUNLOP J, BRECHET Y. Effect of low-temperature recovery treatments on subsequent recrystallization in Al-2.5Mg [J]. Mater Sci Forum, 2007, 550: 381–386.

ZUROB H S, BRECHET Y, DUNLOP J. Quantitative criterion for recrystallization nucleation in single-phase alloys: Prediction of critical strains and incubation times [J]. Acta Mater, 2006, 54: 3983–3990.

PRIMIG S, LEITNER H, KNABL W. Influence of the heating rate on the recrystallization behaviour of molybdenum [J]. Mater Sci Eng A, 2012, 535: 316–324.

FURU T, MARTHINSEN K, NES E. Modeling recrystallization [J]. Mater Sci Technol, 1990, 6: 1093–1102.

SOMERDAY M, HUMPHREYS F J. Recrystallization behavior of supersaturated Al–Mn alloys. Part 1—Al–1.3wt% Mn [J]. Mater Sci Technol, 2003, 19: 20–29.

HUANG K, ENGLER O, LI Y J, MARTHINSEN K. Evolution in microstructure and properties during non-isothermal annealing of a cold-rolled Al–Mn–Fe–Si alloy with different microchemistry states [J]. Mater Sci Eng A, 2015, 628: 216–229.

DAALAND O, NES E. Recrystallization texture development in commercial Al–Mn–Mg alloys [J]. Acta Mater, 1996, 14: 1413–1435.

XIA S L, MA M, ZHANG J X, WANG W X. Effect of heating rate on the microstructure, texture and tensile properties of continuous cast AA 5083 aluminum alloy [J]. Mater Sci Eng A, 2014, 609: 168–176.

LIU W C, RADHAKRISHNAN B. Recrystallization behaviour of a supersaturated Al–Mn alloy [J]. Mater Letters, 2010, 64: 1829–1832.

BIROL Y. Homogenization of a twin-roll cast thin Al–Mn strip [J]. J Alloys Compd, 2009, 471: 122–127.

XIA S L, MA M, ZHANG J X, WANG W X. Effect of heating rate on the microstructure, texture and tensile properties of continuous cast AA 5083 aluminum alloy [J]. Mater Sci Eng A, 2014, 609: 168–176.

LIU W C, RADHAKRISHNAN B. Recrystallization behaviour of a supersaturated Al–Mn alloy [J]. Mater Letters, 2010, 64: 1829–1832.

BIROL Y. Homogenization of a twin-roll cast thin Al–Mn strip [J]. J Alloys Compd, 2009, 471: 122–127.

HUANG Y C, LI Q, XIAO Z B, LIU Y, ZHANG H H. Influence of precipitation on recrystallization texture of AA3104 aluminum alloy [J]. Journal of Central South University, 2015, 22: 3683–3688.

HUANG K, ZHAO Q L, LI Y J, MARTHINSEN K. Two-stage annealing of a cold-rolled Al–Mn–Fe–Si alloy with different microchemistry states [J]. J Mater Process Tech, 2015, 221: 87–99.

LI Y J, ARNBERG L. Quantitative study on the precipitation behavior of dispersoids in DC-cast AA3003 alloy during heating and homogenization [J]. Acta Mater, 2003, 52: 3415–3428.

RADKO K, JAROSLAV P. Recrystallization of previously recovered aluminium [J]. Metal Sci, 1975, 9: 104–110.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Foundation item: Project(2016YFB0300901) supported by National Key R&D Program of China; Project(51421001) supported by the National Natural Science Foundation of China; Project(106112015CDJXY130003) supported by the Fundamental Research Funds for the Central Universities, China

Rights and permissions

About this article

Cite this article

Huang, L., Cao, Lf., Huang, Gj. et al. Effect of pre-recovery on subsequent recrystallization kinetics in moderately deformed and supersaturated Al-Mn alloys. J. Cent. South Univ. 25, 534–542 (2018). https://doi.org/10.1007/s11771-018-3758-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-018-3758-z