Abstract

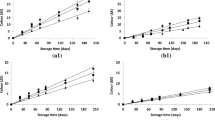

Tamarind pulp powder (TPP) was produced using optimum spray drying conditions, packed in two different packaging materials viz., aluminium laminated polyethylene (ALP) and 4-ply laminate pouches (polythene-aluminium-polythene-paper) and stored under accelerated conditions (40 ± 1 °C temperature, 90 % relative humidity). The powder was analyzed for various quality parameters (moisture content, color, acidity, and powder flowability) at an interval of 7 days upto 70 days of storage period. Both packaging material and storage period showed significant effect on the powder properties. Kinetic study of color change of tamarind pulp powder during storage revealed that color change followed zero order reaction kinetics with a rate constant of 0.495 and 0.369 for the powder packed in ALP and 4-ply laminate, respectively. The magnitude of quality changes of TPP measured during accelerated storage suggested that 4-ply laminate was better than ALP for long term storage of spray dried TPP. The shelf life of TPP under accelerated storage condition was predicted on the basis of flowability of the powder and was calculated to be 53 and 66 days in ALP and 4-ply laminate, respectively.

Similar content being viewed by others

References

M. Obulesu, S. Bhattacharya, Int J Food Prop 14, 538–549 (2011)

E. De Caluwe, K. Halamov, P. Van Damme, African natural plant products: discoveries and challenges in quality control, in Quality control, ed. by H.R. Juliani, J.E. Simon, Chi-Thong Ho (American Chemical Society, Washington DC, 2009), pp. 85–110

K. El-Siddig, H.P.M. Gunasena, B.A. Prasa, D.K.N.G. Pushpakumara, K.V.R. Ramana, P. Vijayanand, J.T. Williams, in Tamarind—Tamarindus indica L. Fruits for the future 1, (Southampton Centre for Underutilized Crops, Southampton, 2006)

A.L. Khandare, G.S. Rao, N. Lakshmaiah, Euro J Clin Nutri 56, 82–85 (2002)

K. Muzaffar, P. Kumar, Drying Technol 34, 142–148 (2016)

S.N. Bhusari, K. Muzaffar, P. Kumar, Powder Technol 266, 354–364 (2014)

S.Y. Quek, N.K. Chok, P. Swedlund, Chem Eng Process 46, 386–392 (2007)

K. Muzaffar, P. Kumar, Powder Technol 279, 179–184 (2015)

Z. Escobedo-Avellaneda, G. Velazquez, J.A. Torres, J. Welti-Chanes, Inclusion of the variability of model parameters on shelf-life estimations for low and intermediate moisture vegetables. LWT-Food Sci Technol 47, 364–370 (2012)

C.A. Breda, E.J. Sanjinez-Argandona, C. de AC Correia, Food Chem 135, 2960–2964 (2012)

P. Garcia-Garcia, A. Lopez-Lopez, A. Garrido-Fernandez, J Food Eng 84, 569–575 (2008)

N. Sanjuan, J. Bom, G. Clemente, A. Mulet, Changes in the quality of dehydrated broccoli florets during storage. J Food Eng 62, 15–21 (2004)

K. Muzaffar, P. Kumar, Conceptual framework & innovations, in Agroecology and food sciences, ed. by G.C. Mishra (Krishi Sanskriti Publications, New Delhi, 2015), pp. 65–67

AOAC, 19th edn. (Association of Official Analytical Chemists, Washington DC, 2012)

S. Rangana, Hand book of analysis and quality control for fruits and vegetable products, 2nd edn. (Tata McGraw Hall Publishing Company Lid, New Delhi, 1986)

K. Muzaffar, P. Kumar, Drying Technol (2015). doi:10.1080/07373937.2015.1080724

P. Kumar, H.N. Mishra, Int J Dairy Technol 59, 22–28 (2006)

L. Greenspan, Humidity fixed points of binary saturated aqueous solutions. J Res Natl Bur Stand 81, 89–96 (1977)

J. Crank, The mathematics of diffusion, 2nd edn. (Oxford University Press, Oxford, 1999), pp. 89–103

S. Jaya, H. Das, J Food Process Preserv 29, 45–62 (2005)

A.K. Chauhan, V. Patil, Powder Technol 239, 86–93 (2013)

F. Liu, X. Cao, H. Wang, X. Liao, Powder Technol 204, 159–166 (2010)

D. Janjatovic, M. Benkovic, S. Srecec, D. Jezek, I. Spoljaric, I. Bauman, Adv Powder Technol 23, 620–631 (2012)

M.A.J.S. Van Bockel, J Food Sci 61, 477–489 (1996)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Muzaffar, K., Kumar, P. Quality assessment and shelf life prediction of spray dried tamarind pulp powder in accelerated environment using two different packaging materials. Food Measure 11, 265–271 (2017). https://doi.org/10.1007/s11694-016-9393-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-016-9393-1