Abstract

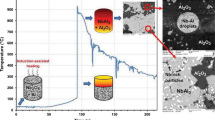

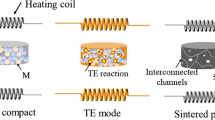

Ternary Ni-Al-Al12Mg17 and binary Ni-Al reactive materials were obtained by cold spraying. The reactive performance of both materials was compared to explore the influence of the Al12Mg17 additive. According to differential scanning calorimetry–thermogravimetric analysis–derivative thermogravimetry, the Ni-Al-Al12Mg17 thermal explosion reaction produced a peak at 480 °C, being 160 °C lower than that of binary Ni-Al. The high-resolution element surface distribution clearly showed the microstructure evolution after controlled annealing and revealed that the rapid oxidation reaction of liquid Mg played a critical role in the occurrence of the thermal explosion reaction in air. During the self-propagating combustion process, the Al12Mg17 additive acted as “ignition spots,” and the Ni-Al intermetallic reaction was ignited by combustion of Mg. The sustained power provided by the Mg combustion promoted the continuous reaction in the Ni-Al matrix. The combustion wave velocity of the Ni-Al-Al12Mg17 material was almost doubled, from 60-100 to 150-200 mm s−1, demonstrating the suitability of the Al12Mg17 additive for enhancing the performance of Ni-Al-based reactive material.

Similar content being viewed by others

References

S.H. Fischer and M.C. Grubelich, A Survey of Combustible Metals, Thermites, and Intermetallics for Pyrotechnic Applications, in 32nd Joint Propulsion Conference and Exhibit, Orlando, FL, USA, 1996

C.T. Wei, E. Vitali, F. Jiang, S.W. Du, D.J. Benson, K.S. Vecchio, N.N. Thadhani, and M.A. Meyers, Quasi-Static and Dynamic Response of Explosively Consolidated Metal-Aluminum Powder Mixtures, Acta Mater., 2012, 60, p 1418-1432

B.B. Aydelotte and N.N. Thadhani, Mechanistic Aspects of Impact Initiated Reactions in Explosively Consolidated Metal + Aluminum Powder Mixtures, Mater. Sci. Eng. A, 2013, 570, p 164-171

A.M. Marquez, C.H. Braithwaite, T.P. Weihs, N.M. Krywopusk, D.J. Gibbins, K.S. Vecchio, and M.A. Meyers, Fragmentation and Constitutive Response of Tailored Mesostructured Aluminum Compacts, J. Appl. Phys., 2016, 119, p 145903

P. Church, R. Claridge, P. Ottley, I. Lewtas, N. Harrison, P. Gould, C. Braithwaite, and D. Williamson, Investigation of a Nickel-Aluminum Reactive Shaped Charge Liner, J. Appl. Mech., 2013, 80, p 031701

G. Byun, J. Kim, C. Lee, S.J. Kim, and S. Lee, Kinetic Spraying Deposition of Reactive-Enhanced Al-Ni Composite for Shaped Charge Liner Applications, J. Therm. Spray Technol., 2016, 25(3), p 483-493

D.B. Nielson, R.M. Truitt, and B.N. Ashcroft, Reactive Material Enhanced Projectiles and Related Methods, U.S. Patent 8,122,833, 2012

A.K. Stover, N.M. Krywopusk, J.D. Gibbins, and T.P. Weihs, Mechanical Fabrication of Reactive Metal Laminate Powders, J. Mater. Sci., 2014, 49, p 5821-5830

A.K. Stover, N.M. Krywopusk, G.M. Fritz, S.C. Barron, J.D. Gibbins, and T.P. Weihs, An Analysis of the Microstructure and Properties of Cold-Rolled Ni:Al Laminate Foils, J. Mater. Sci., 2013, 48, p 5917-5929

X. Qiu, J. Graeter, L. Kecskes, and J. Wang, Exothermic Reactions in Cold-Rolled Ni/Al Reactive Multilayer Foils, J. Mater. Res., 2008, 23, p 367-375

H. Sieber, J.S. Park, J. Weissmüller, and J.H. Perepezko, Structural Evolution and Phase Formation in Cold-Rolled Aluminum-Nickel Multilayers, Acta Mater., 2001, 49, p 1139-1151

E.M. Hunt and M.L. Pantoya, Impact Sensitivity of Intermetallic Nanocomposites: A Study on Compositional and Bulk Density, Intermetallics, 2010, 18, p 1612-1616

K. Morsi, The Diversity of Combustion Synthesis Processing: A Review, J. Mater. Sci., 2012, 47, p 68-92

J.D. Gibbins, A.K. Stover, N.M. Krywopusk, K. Woll, and T.P. Weihs, Properties of Reactive Al:Ni Compacts Fabricated by Radial Forging of Elemental and Alloy Powders, Combust. Flame, 2015, 162, p 4408-4416

D. Adams, Reactive Multilayers Fabricated by Vapor Deposition: A Critical Review, Thin Solid Films, 2015, 576, p 98-128

E. Ma, C.V. Thompson, L.A. Clevenger, and K.N. Tu, Self-Propagating Explosive Reactions in Al/Ni Multilayer Thin Films, Appl. Phys. Lett., 1990, 57, p 1262-1264

A.S. Rogachev, S.G. Vadchenko, F. Baras, O. Politano, S. Rouvimov, N.V. Sachkova, and A.S. Mukasyan, Structure Evolution and Reaction Mechanism in the Ni/Al Reactive Multilayer Nanofoils, Acta Mater., 2014, 66, p 86-96

M.D. Grapes and T.P. Weihs, Exploring the Reaction Mechanism in Self-Propagating Al/Ni Multilayers by Adding Inert Material, Combust. Flame, 2016, 172, p 105-115

A. Bacciochini, M.I. Radulescu, Y. Charron-Tousignant, J. Van Dyke, M. Nganbe, M. Yandouzi, J.J. Lee, and B. Jodoin, Enhanced Reactivity of Mechanically-Activated Nano-scale Gasless Reactive Materials Consolidated by Coldspray, Surf. Coat. Technol., 2012, 206, p 4343-4348

S.W. Dean, J.K. Potter, R.A. Yetter, T.J. Eden, V. Champagne, and M. Trexler, Energetic Intermetallic Materials Formed by Cold Spray, Intermetallics, 2013, 43, p 121-130

F. Gärtner, T. Stoltenhoff, T. Schmidt, and H. Kreye, The Cold Spray Process and Its Potential for Industrial Applications, J. Therm. Spray Technol., 2006, 15, p 223-232

A. Bacciochini, M.I. Radulescu, M. Yandouzi, G. Maines, J.J. Lee, and B. Jodoin, Reactive Structural Materials Consolidated by Cold Spray: Al-CuO Thermite, Surf. Coat. Technol., 2013, 226, p 60-67

C. Lee and J. Kim, Microstructure of Kinetic Spray Coatings: A Review, J. Therm. Spray Technol., 2015, 24(4), p 592-610

V.K. Champagne, The Cold Spray Materials Deposition Process, Woodhead, Cambridge, 2007, p 63-70

R.N. Raoelison, Ch. Verdy, and H. Liao, Cold Gas Dynamic Spray Additive Manufacturing Today: Deposit Possibilities, Technological Solutions and Viable Applications, Mater. Des., 2017, 133, p 266-287

B.B. Aydelotte, Fragmentation and Reaction of Structural Energetic Materials, Ph.D. Dissertation, Georgia Institute of Technology, 2013

H. Lee, H. Shin, S. Lee, and K. Ko, Effect of Gas Pressure on Al Coatings by Cold Gas Dynamic Spray, Mater. Lett., 2008, 62, p 1579-1581

H.L. Zhao, C.W. Tan, X.D. Yu, X.J. Ning, Z.H. Nie, H.N. Cai, F.C. Wang, and Y. Cui, Enhanced Reactivity of Ni-Al Reactive Material Formed by Cold Spraying Combined with Cold-Pack Rolling, J. Alloys Compd., 2018, 741, p 883-894

K.V. Manukyan, B.A. Mason, L.J. Groven, Y.C. Lin, M. Cherukara, S.F. Son, A. Strachan, and A.S. Mukasyan, Tailored Reactivity of Ni + Al Nanocomposites: Microstructural Correlations, J. Phys. Chem. C, 2012, 116, p 21027-21038

A. Bacciochini, S. Bourdon-Lafleur, C. Poupart, M. Radulescu, and B. Jodoin, Ni-Al Nanoscale Energetic Materials: Phenomena Involved during the Manufacturing of Bulk Samples by Cold Spray, J. Therm. Spray Technol., 2014, 23, p 1142-1148

B.E. Homan, K.L. McNesby, J. Ritter, J. Colburn, A. Brant, and R. Pandey, Investigations of the Energy Release Mechanisms of Aluminum-Nickel Reactive Material System, The U.S. Army Research Laboratory, Orlando, 2008

Y.L. Shoshin, R.S. Mudryy, and E.L. Dreizin, Preparation and Characterization of Energetic Al-Mg Mechanical Alloy Powders, Combust. Flame, 2002, 128, p 259-269

Y.L. Shoshin and E.L. Dreizin, Particle Combustion Rates for Mechanically Alloyed Al-Ti and Aluminum Powders Burning in Air, Combust. Flame, 2006, 145, p 714-722

Y. Wang, W. Jiang, X.F. Zhang, H.Y. Liu, Y.Q. Liu, and F.S. Li, Energy Release Characteristics of Impact-Initiated Energetic Aluminum-Magnesium Mechanical Alloy Particles with Nanometer-Scale Structure, Thermochim. Acta, 2011, 512, p 233-239

K.R. Overdeep, K.J.T. Livi, D.J. Allen, N.G. Glumac, and T.P. Weihs, Using Magnesium to Maximize Heat Generated by Reactive Al/Zr Nanolaminates, Combust. Flame, 2015, 162, p 2855-2864

T.A. Roberts, R.L. Burton, and H. Krier, Ignition and Combustion of Aluminummagnesium Alloy Particles in O2 at High Pressures, Combust. Flame, 1993, 92, p 125-143

J. Ragani, P. Donnadieu, C. Tassin, and J.J. Blandin, High-Temperature Deformation of the Γ-Mg17Al12 Complex Metallic Alloy, Scr. Mater., 2011, 65, p 253-256

H.Y. Bu, M. Yandouzi, C. Lu, D. MacDonald, and B. Jodoin, Cold Spray Blended Al + Mg17Al12 Coating for Corrosion Protection of AZ91D Magnesium Alloy, Surf. Coat. Technol., 2012, 207, p 155-162

L. Plazanet and F. Nardou, Reaction Process during Relative Sintering of NiAl, J. Mater. Sci., 1998, 33, p 2129-2136

M.A. Meyers, Dynamic Behavior of Materials, Wiley, New York, 1994

E.G. Colgan and J.W. Mayer, Initial Phase Formation and Dissociation in the Thin-Film Ni/Al System, J. Appl. Phys., 1985, 58, p 4125-4129

A.A. Nayeb-Hashemi and J.B. Clark, The Mg-Ni (Magnesium-Nickel) System, Bull. Alloy Phase Diagr., 1985, 6, p 238-244

H.T. Huang, M.S. Zou, X.Y. Guo, R.J. Yang, and Y.K. Li, Analysis of the Aluminum Reaction Efficiency in a Hydro-Reactive Fuel Propellant Used for a Water Ramjet, Combust. Explos. Shock Waves, 2013, 49, p 541-547

J. Won, G. Bae, K. Kang, C. Lee, S.J. Kim, K.A. Lee, and S. Lee, Bonding, Reactivity, and Mechanical Properties of the Kinetic-Sprayed Deposition of Al for a Thermally Activated Reactive Cu Liner, J. Therm. Spray Technol., 2014, 23(5), p 818-826

F. Czerwinski, The Oxidation Behaviour of an AZ91D Magnesium Alloy at High Temperatures, Acta Mater., 2002, 50, p 2639-2654

H.X. Dong, Y. Jiang, Y.H. He, M. Song, J. Zou, N.P. Xu, B.Y. Huang, C.T. Liu, and P.K. Liaw, Formation of Porous Ni-Al Intermetallics through Pressureless Reaction Synthesis, J. Alloys Compd., 2009, 484, p 907-913

K. Morsi, Reaction Synthesis Processing of Ni-Al Intermetallic Materials, Mater. Sci. Eng. A, 2001, 299, p 1-15

M. Schoenitz and E.L. Dreizin, Oxidation Processes and Phase Changes in Metastable Al-Mg Alloys, J. Propuls. Power, 2004, 20, p 1064-1068

E.I. Popov, L.Y. Kashporov, V.M. Mal’tsev, and A.L. Breiter, Combustion Mechanism of Aluminum-Magnesium Alloy Particles, Combust. Explos. Shock Waves, 1973, 9, p 204-208

Y. Aly and E.L. Dreizin, Ignition and Combustion of Al·Mg Alloy Powders Prepared by Different Techniques, Combust. Flame, 2015, 162, p 1440-1447

Q.C. Fan, H.F. Chai, and Z.H. Jin, Dissolution–Precipitation Mechanism of Self-Propagating High-Temperature Synthesis of Mononickel Aluminide, Intermetallics, 2001, 9, p 609-619

R.H. Chen, C. Suryanarayana, and M. Chaos, Combustion Characteristics of Mechanically Alloyed Ultrafine-Grained Al-Mg Powders, Adv. Eng. Mater., 2006, 8, p 563-567

Y. Aly, M. Schoenitz, and E.L. Dreizin, Ignition and Combustion of Mechanically Alloyed Al-Mg Powders with Customized Particle Sizes, Combust. Flame, 2013, 160, p 835-842

Z.A. Munir and U. Anselmi-Tamburini, Self-Propagating Exothermic Reactions: The Synthesis of High-Temperature Materials by Combustion, Mater. Sci. Rep., 1989, 3, p 279-365

W.M. Haynes, CRC Handbook of Chemistry and Physics, 93rd ed., CRC, Boca Raton, 2012

Acknowledgments

The authors would like to acknowledge the State Key Laboratory of Tribology (SKLT) in Tsinghua University for technical support in the high-resolution component analysis. We also thank LetPub (www.letpub.com) for linguistic assistance during the preparation of this manuscript. This work was supported by the National Natural Science Foundation of China (51671031).

Conflict of interest

The authors declare that they have no conflicts of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, H., Ning, X., Tan, C. et al. Influence of Al12Mg17 Additive on Performance of Cold-Sprayed Ni-Al Reactive Material. J Therm Spray Tech 28, 780–793 (2019). https://doi.org/10.1007/s11666-019-00848-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-019-00848-2