Abstract

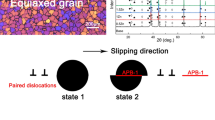

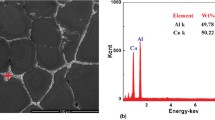

Binary Al-Zn alloys with different Zn contents were fabricated by casting and heat treatment. Analysis of mechanical properties showed that the hardness and tensile strength of Al-Zn alloys increased with increased Zn content, with the post-heat treatment hardness and ultimate tensile strength of Al-49Zn alloy reaching as high as 152 HV and 330 MPa, respectively. Meanwhile, the plasticity and toughness of Al-Zn alloys decreased with increased Zn content. Solid-solution strengthening was the main strengthening mechanism for Al-Zn alloys, and Orowan strengthening was also observed in Al-49Zn alloy. The fracture mode of Al-20Zn and Al-35Zn alloys was ductile, whereas Al-20Zn alloy showed good impact toughness. This work provided a basis for further improving the cast component design of the Al-Zn-X system.

Similar content being viewed by others

Change history

04 May 2023

A Correction to this paper has been published: https://doi.org/10.1007/s11665-023-08254-0

References

I. Černý, J. Sís, and D. Mikulová, Short Fatigue Crack Growth in an Aircraft Al-Alloy of a 7075 Type After Shot Peening, Surf. Coat. Technol., 2014, 243(12), p 20–27

Ł. Kaczmarek, M. Stegliński, J. Sawicki, J. Świniarski, D. Batory, K. Kyzioł, Ł. Kołodziejczyk, W. Szymański, P. Zawadzki, and D. Kottfer, Optimization of the Heat Treatment and Tribological Properties of 2024 and 7075 Aluminium Alloys, Arch. Metall. Mater., 2013, 58(2), p 535–540

K. Kyzioł, K. Koper, M. Środa, M. Klich, and Ł. Kaczmarek, Influence of Gas Mixture during N+ Ion Modification Under Plasma Conditions on Surface Structure and Mechanical Properties of Al-Zn Alloys, Surf. Coat. Technol., 2015, 278(6), p 30–37

K. Bewilogua, G. Bräuer, A. Dietz, J. Gäbler, G. Goch, B. Karpuschewski, and B. Szyszka, Surface Technology for Automotive Engineering, CIRP Ann. Manuf. Technol., 2009, 58(2), p 608–627

S.L. Pramod, A.K. Prasada Rao, B.S. Murty, and S.R. Bakshi, Effect of Sc Addition on the Microstructure and Wear Properties of A356 Alloy and A356-TiB2 In Situ Composite, Mater. Des., 2015, 78, p 85–94

W.D. Zhang, Y. Liu, J. Yang, J.Z. Dang, H. Xu, and Z.M. Du, Effects of Sc Content on the Microstructure of As-Cast Al-7wt.% Si Alloys, Mater. Charact., 2012, 66, p 104–110

J.J. Wang, Z.M. Zhang, A.B. Phillion, S.Z. Shang, and G.M. Lu, Alloy Development and Reheating Process Exploration of Al-Si Casting Alloys with Globular Grains for Thixoforming, J. Mater. Res., 2016, 31(16), p 2482–2492

Y. Zheng, W.L. Xiao, S.J. Ge, W.T. Zhao, S.J. Hanada, and C.L. Ma, Effects of Cu Content and Cu/Mg Ratio on the Microstructure and Mechanical Properties of Al-Si-Cu-Mg Alloys, J. Alloys Compd., 2015, 649, p 291–296

R. Chen, Q.Y. Xu, H.T. Guo, Z.Y. Xia, Q.F. Wu, and B.C. Liu, Modeling the Precipitation Kinetics and Tensile Properties in Al-7Si-Mg Cast Aluminum Alloys, Mater. Sci. Eng. A, 2017, 685, p 403–416

T.B. Massalski, Alloy Phase diagrams, Materials Park, OH, ASM International, 1993, p 239

X. Sauvage, M.Y. Murashkin, B.B. Straumal, E.V. Bobruk, and R.Z. Valiev, Ultrafine Grained Structures Resulting from SPD-Induced Phase Transformation in Al-Zn Alloys, Adv. Eng. Mater., 2015, 17(12), p 1821–1827

A.A. Mazilkin, B.B. Straumal, E. Rabkin, B. Baretzky, S. Enders, S.G. Protasova, O.A. Kogtenkova, and R.Z. Valiev, Softening of Nanostructured Al-Zn and Al-Mg Alloys After Severe Plastic Deformation, Acta Mater., 2006, 54(15), p 3933–3939

N.Q. Chinh, P. Jenei, J. Gubicza, E.V. Bobruk, R.Z. Valievb, and T.G. Langdon, Influence of Zn Content on the Microstructure and Mechanical Performance of Ultrafine-Grained Al-Zn Alloys Processed by High-Pressure Torsion, Mater. Lett., 2017, 186, p 334–337

W.B. Zhou, C.Y. Liu, P.F. Yu, B. Zhang, Z.Y. Ma, K. Luo, M.Z. Ma, and R.P. Liu, Effect of Scandium on Microstructure and Mechanical Properties of High Zinc Concentration Aluminum Alloys, Mater. Charact., 2017, 127, p 371–378

S.S. Shin, K.M. Lim, and I.M. Park, Characteristics and Microstructure of Newly Designed Al-Zn-Based Alloys for the Die-Casting Process, J. Alloys Compd., 2016, 671, p 517–526

C.Y. Liu, B. Qu, Z.Y. Ma, M.Z. Ma, and R.P. Liu, Recrystallization, Precipitation, and Resultant Mechanical Properties of Rolled Al-Zn Alloy After Aging, Mater. Sci. Eng. A, 2016, 657, p 284–290

C.Y. Liu, M.Z. Ma, R.P. Liu, and K. Luo, Evaluation of Microstructure and Mechanical Properties of Al-Zn Alloy During Rolling, Mater. Sci. Eng. A, 2016, 654, p 436–441

C.Y. Liu, L. Yu, M.Z. Ma, R.P. Liu, and Z.Y. Ma, Dynamic Precipitation of Al-Zn Alloy During Rolling and Accumulative Roll Bonding, Philos. Mag. Lett., 2015, 95(11), p 539–546

C.Y. Liu, H.J. Jiang, C.X. Wang, H.Q. Qi, Y.B. Li, M.Z. Ma, and R.P. Liu, Static and Dynamic Precipitation Behavior of the Al-20wt.% Zn Alloy, Chin. Phys. Lett., 2016, 33(5), p 056101

C.Y. Liu, B. Zhang, P.F. Yu, R. Jing, M.Z. Ma, and R.P. Liu, Microstructures and Mechanical Properties of Al/Zn Composites Prepared by Accumulative Roll Bonding and Heat Treatment, Mater. Sci. Eng. A, 2013, 580, p 36–40

C.Y. Liu, M.Z. Ma, R.P. Liu, L. Yu, and K. Luo, Effect of Zn Particles on Ductility of the Accumulative Roll-Bonding Composites, Sci. China Phys. Mech. Astron., 2015, 58(10), p 104601

B. Dang, C.C. Liu, F. Liu, Y.Z. Liu, and Y.B. Li, Effect of As-Solidified Microstructure on Subsequent Solution-Treatment Process for A356 Al Alloy, Trans. Nonferrous Metal Soc. China, 2016, 26(3), p 634–642

S. Meenia, F. Khan, S. Babu, R.J. Immanuel, and S.K. Panigrahi, Particle Refinement and Fine-Grain Formation Leading to Enhanced Mechanical Behaviour in a Hypo-Eutectic Al-Si Alloy Subjected to Multi-pass Friction Stir Processing, Mater. Charact., 2016, 113, p 134–143

W.M. Jiang, Z.T. Fan, X. Chen, B.J. Wang, and H.B. Wu, Combined Effects of Mechanical Vibration and Wall Thickness on Microstructure and Mechanical Properties of A356 Aluminum Alloy Produced by Expendable Pattern Shell Casting, Mater. Sci. Eng. A, 2014, 619, p 228–237

C.Y. Liu, Q. Wang, Y.Z. Jia, B. Zhang, R. Jing, M.Z. Ma, Q. Jing, and R.P. Liu, Effect of W Particles on the Properties of Accumulatively Roll-Bonded Al/W Composites, Mater. Sci. Eng. A, 2012, 547, p 120–124

C.Y. Liu, Q. Wang, Y.Z. Jia, B. Zhang, R. Jing, M.Z. Ma, Q. Jing, and R.P. Liu, Evaluation of Mechanical Properties of 1060-Al Reinforced with WC Particles via Warm Accumulative Roll Bonding Process, Mater. Des., 2013, 43, p 367–372

C.Y. Liu, P.F. Yu, X.Y. Wang, M.Z. Ma, and R.P. Liu, Preparation of High-Strength Al-Mg-Si-Cu-Fe Alloy via Heat Treatment and Rolling, Int. J. Miner. Met. Mater., 2014, 21(7), p 702–710

D.F. Li, C.X. Cui, X. Wang, Q.Z. Wang, C. Chen, and S.Q. Liu, Microstructure Evolution and Enhanced Mechanical Properties of Eutectic Al-Si Die Cast Alloy by Combined Alloying Mg and La, Mater. Des., 2016, 90, p 820–828

K. Natori, H. Utsunomiya, and T. Tanaka, Improvement in Formability of Semi-Solid Cast Hypoeutectic Al-Si Alloys by Equal-Channel Angular Pressing, J. Mater. Process. Technol., 2017, 240, p 240–248

Acknowledgments

This work was funded by the Research Program of Science and Technology of Guangxi (No. GKAB16380021), the Guangxi “Bagui” Teams for Innovation, Educational Commission of Guangxi of China (No. KY2015ZD050), and Collaborative Innovation Center for Exploration of Hidden Nonferrous Metal Deposits and Development of New Materials in Guangxi.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Zhou, W.B., Teng, G.B., Liu, C.Y. et al. Microstructures and Mechanical Properties of Binary Al-Zn Alloys Fabricated by Casting and Heat Treatment. J. of Materi Eng and Perform 26, 3977–3982 (2017). https://doi.org/10.1007/s11665-017-2852-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-017-2852-y