Abstract

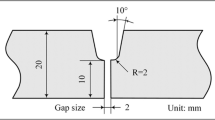

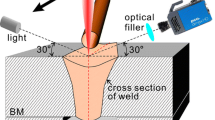

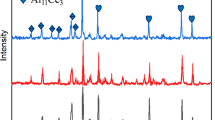

Butt-welded 2-mm-thick high-strength aluminum alloys have been welded using a hybrid fiber laser and pulsed arc heat source system with the ER5356 filler. The microstructure, size of precipitates, texture, grain size and shape, change of strengthening elements, mechanical properties, and surface-based fatigue fracture characteristics of hybrid-welded joints were investigated in detail. The results indicate that the hybrid welds and the unaffected base materials have the lowest and largest hardness values, respectively, compared with the heat-affected zone. It is resonably believed that the elemental loss, coarse grains, and changed precipitates synthetically produce the low hardness and tensile strengths of hybrid welds. Meanwhile, the weaker grain boundary inside welds appears to initiate a microcrack. Besides, there exists an interaction of fatigue cracks and gas pores and microstructures.

Similar content being viewed by others

References

B. Hu and I.M. Richardson, Microstructure and Mechanical Properties of AA7075(T6) Hybrid Laser/GMA Welds, Mater. Sci. Eng. A, 2007, 459(1–2), p 94–100

A. Hirose, N. Kurosawa, K.F. Kobayashi, H. Todaka, and H. Yamaoka, Quantitative Evaluation of Softened Regions in Weld Heat-affected Zones of 6061-T6 Aluminum Alloy—Characterizing of the Laser Beam Welding Process, Metall. Mater. Trans. A, 1999, 30(8), p 2115–2120

J.F. Tu and A.G. Paleocrassas, Fatigue Crack Fusion in Thin-Sheet Aluminum Alloys AA7075-T6 Using Low-Speed Fiber Laser Welding, J. Mater Process Technol., 2011, 211(1), p 95–102

C. Bagger and F.O. Olsen, Review of Laser Hybrid Welding, J. Laser. Appl., 2011, 17(6), p 2–14

R.S. Huang, L. Kang, and X. Ma, Microstructure and Phase Composition of a Low-Power YAG Laser-MAG Welded Stainless Steel Joint, J. Mater. Eng. Perform., 2008, 17(6), p 928–935

H. Staufer, Laser Hybrid Welding in the Automotive Industry, Weld. J., 2007, 86(10), p 36–40

H. Yonetani, Laser-MIG Hybrid Welding to Aluminium Alloy Carbody Shell for Railway Vehicles, Weld. Int., 2008, 22(10), p 701–704

T.W. Nelson, R.J. Steel, and W.J. Arbegast, In Situ Thermal Studies and Post-weld Mechanical Properties of Friction Stir Welds in Age Hardenable Aluminum Alloys, Sci. Technol. Weld. Join., 2003, 8, p 283–288

A. Deschamps, S. Ringeval, G. Texier, and D.L. Delfaut, Quantitative Characterization of the Microstructure of an Electron-beam Welded Medium Strength Al-Zn-Mg Alloy, Mater. Sci. Eng. A, 2009, 517(1–2), p 361–368

L.M. Liu and X.D. Qi, Effects of Copper Addition on Microstructure and Strength of the Hybrid Laser-TIG Welded Joints Between Magnesium Alloy and Mild Steel, J. Mater. Sci., 2009, 44(21), p 5725–5731

C.G. Rhodes, M.W. Mahoney, W.H. Bingel, R.A. Spurling, and C.C. Bampton, Effect of Friction Stir Welding on Microstructure of 7075 Aluminum, Scripta Mater., 1997, 36(1), p 69–75

T. Azimzadegan and S. Serajzadeh, An Investigation into Microstructures and Mechanical Properties of AA7075-T6 During Friction Stir Welding at Relatively High Rotational Speeds, J. Mater. Eng. Perform., 2010, 19(9), p 1256–1263

L.K. Berg, J. Gjønnes, V. Hansen, X.Z. Li, M.K. Wedel, G. Waterloo, D. Schryvers, and L.R. Wallenberg LR, GP-zones in Al-Zn-Mg Alloys and Their Role in Artificial Aging, Acta Mater., 2001, 49(17), p 3443–3451

A. Deschamps, Y. Brechet, and F. Livet, Influence of Copper Addition on Precipitation Kinetics and Hardening in Al-Zn-Mg Alloy, Mater. Sci. Technol., 1999, 15(9), p 993–1000

S.C. Wu, X. Yu, R.Z. Zuo, W.H. Zhang, H.L. Xie, and J.Z. Jiang, Porosity, Element Loss and Strength Model on Softening Behavior of Hybrid Laser Arc Welded Al-Zn-Mg-Cu Alloy with Synchrotron Radiation Analysis, Weld. J., 2013, 92(3), p 64–71

G. Mathers, The Welding of Aluminium and Its Alloys, Woodhead Publishing Ltd., New York, 2002

J. Wong, M. Froba, J.W. Elmer, P.A. Waide, and E.M. Larson, In-Situ Phase Mapping and Transformation Study in Fusion Welds, J. Mater. Sci., 1999, 32(6), p 1493–1500

H. Zhang, H. Toda, H. Hara, M. Kobayashi, T. Kobayashi, D. Sugiyama, N. Kuroda, and K. Uesugi, Three-Dimensional Visualization of the Interaction Between Fatigue Crack and Micropores in an Aluminum Alloy using Synchrotron x-Ray Microtomography, Metall. Mater. Trans. A, 2007, 38(8), p 1774–1785

P. Li, P.D. Lee, D.M. Maijer, and T.C. Lindley, Quantification of the Interaction Within Defect Populations on Fatigue Behavior in an Aluminum Alloy, Acta Mater., 2009, 57(12), p 3539–3548

A.K. Shukla and W.A. Baeslack, Orientation Relationships and Morphology of S Phase in Friction Stir Welded Al-Cu-Mg Alloy, J. Mater. Sci., 2009, 44(2), p 676–679

T. Ma and G.D. Ouden, Softening Behaviour of Al-Zn-Mg Alloys Due to Welding, Mater. Sci. Eng. A, 1999, 266(1–2), p 198–204

L. Cui, X.Y. Li, D.Y. He, L. Chen, and S.L. Gong, Effect of Nd YAG Laser Welding on Microstructure and Hardness of an Al-Li Based Alloy, Mater. Charact., 2012, 71(9), p 95–102

S. Dev, B.S. Murty, and K.P. Rao, Effects of Base and Filler Chemistry and Weld Techniques on Equiaxed Zone Formation in Al-Zn-Mg Alloy Welds, Sci. Technol. Weld. Join., 2008, 13(7), p 598–606

J.R. Lg Hector, Y.L. Chen, S. Agarwal, and C.L. Briant, Texture Characterization of Autogenous Nd:YAG Laser Welds in AA5182-O and AA6111-T4 Aluminum Alloys, Metall Mater Trans A, 2004, 35(9), p 3032–3038

Y.S. Sato, M. Urata, H. Kokawa, and K. Ikeda, Hall-Petch Relationship in Friction Stir Welds of Equal Channel Angular-Pressed Aluminium Alloys, Mater. Sci. Eng A, 2003, 354(1-2), p 298–305

F.S. Jaberi and A.H. Kokabi, Influence of Nickel and Manganese on Microstructure and Mechanical Properties of Shielded Metal Arc-Welded API-X80 Steel, J. Mater. Eng. Perform., 2012, 21(7), p 1447–1454

W. Hepples, M.C. Thornton, and N.J.H. Holroyd, Microstructural Characterization of White Zones in Weldable 7000 Series Alloys, J. Mater. Sci., 1992, 27(21), p 5720–5726

G. Çam and M. Koçak, Microstructural and Mechanical Characterization of Electron Beam Welded Al-Alloy 7020, J. Mater. Sci., 2007, 42(17), p 7154–7161

Acknowledgments

The authors are grateful for the financial support from the Fundamental Research Funds for the Central Universities (No.: 2682013CX030), the China Postdoctoral Science Foundation (No.: 2013M531980) and the Open Research Fund Program of the State Key Lab. of Traction Power (No.: TPL1302).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, S.C., Hu, Y.N., Song, X.P. et al. On the Microstructural and Mechanical Characterization of Hybrid Laser-Welded Al-Zn-Mg-Cu Alloys. J. of Materi Eng and Perform 24, 1540–1550 (2015). https://doi.org/10.1007/s11665-015-1408-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-015-1408-2