Abstract

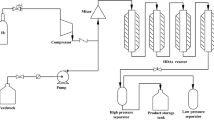

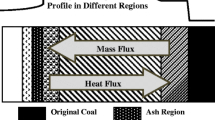

The characteristics of gas evolution from Dachengzi oil shale pyrolysis under different temperatures were experimentally investigated using a fixed bed reactor and then were evaluated by integrating thermodynamic equilibrium simulation employing HSC Chemistry program and Sandia PSR kinetics simulation in this paper. The experiment results indicate that the non-condensable gases contain much higher CO2, CH4 and H2 and lower CO and C2–C4 hydrocarbons in terms of volume percentages, and mainly consist of CO2 and CH4 as well as some minor gases in terms of mass distribution. CO2, CO and H2 are firstly produced followed by the generation of light hydrocarbons. The HSC calculation results present that some C2 and C2+ hydrocarbons disappear in the predicted gaseous products thermodynamically, and the nitrogen- and sulfur-containing gases mainly are N2 and H2S, respectively. Then, the normalized HSC species are inputted into the Sandia PSR code by three methods, i.e., the CHO input method, the regional input method and the individual input method, considering the potential kinetic constraints. Some C2 and C2+ hydrocarbons appear in the predicted gaseous products based on the three methods. The regional input method demonstrates that more H2 and CO are produced at higher temperature, which agrees with the experimental results. And more C2H4 and C2H2 release at higher temperature depending on the enhanced secondary gas cracking reactions. The peak concentration of every gas product is obtained at higher temperature with lower value compared to the experimental results possibly due to ignoring the effect of the shale ash. The individual input method indicates that C2 and C3 hydrocarbons are generated after the formation of CH4, CO, CO2 and H2. The change trends of CO2, CO and H2 obtained from the experiment and simulation with rising temperature are very similar, but those for CH4 are different, due to most likely certain limitations of a fixed bed reactor as a reaction system. Combining the HSC and PSR calculations, the obtained gas products are closer to the realistic situation.

Similar content being viewed by others

References

Adams MJ, Awaja F, Bhargava S, Grocott S, Romeo M. Prediction of oil yield from oil shale minerals using diffuse reflectance infrared Fourier transform spectroscopy. Fuel. 2014;84(14–15):1986–91.

Na JG, Im CH, Chung SH, Lee KB. Effect of oil shale retorting temperature on shale oil yield and properties. Fuel. 2012;95:131–5.

Liu QQ, Han XX, Li QY, Huang YR, Jiang XM. TG–DSC analysis of pyrolysis process of two Chinese oil shales. J Therm Anal Calorim. 2014;116:511–7.

Moine EC, Bouamoud R, EI Hamidi A, Khachani M, Halim M, Arsalane S. Mineralogical characterization and non-isothermal pyrolysis kinetics of Moroccan Rif oil shale. J Therm Anal Calorim. 2018;131:993–1004.

Altun NE, Hicyilmaz C, Hwang JY, Suat Bağci A, Kök MV. Oil shales in the world and Turkey; reserves, current situation and future prospects: a review. Oil Shale. 2006;23(3):211–27.

Kök MV, Şengüler İ. Geological and thermal characterization of Eskişehir region oil shales. J Therm Anal Calorim. 2014;116:367–72.

Gerasimov G, Volkov E. Modeling study of oil shale pyrolysis in rotary drum reactor by solid heat carrier. Fuel Process Technol. 2015;139:108–16.

Jaber JO, Probert SD. Non-isothermal thermogravimetry and decomposition kinetics of two Jordanian oil shales under different processing conditions. Fuel Process Technol. 2000;63(1):57–70.

Wang W, Ma Y, Li SY, Yue CT, Wu JX, Teng JS. Pyrolysis characteristics of Longkou oil shale under optimized condition. J Therm Anal Calorim. 2016;125:983–90.

Kök MV, Pamir R. Pyrolysis kinetics of oil shales determined by DSC and TG/DTG. Oil Shale. 2003;20:57–68.

Kök MV. Evaluation of Turkish oil shales-thermal analysis approach. Oil Shale. 2001;18(2):131–8.

Kök MV. Thermal investigation of Seyitomer oil shale. Thermochim Acta. 2001;369(1–2):149–55.

Kök MV, Sengüler I, Hufnagel H, Sonel N. Thermal and geochemical investigation of Seyitömer oil shale. Thermochim Acta. 2001;371:111–9.

Wang W, Li SY, Yue CT, Ma Y. Multistep pyrolysis kinetics of North Korean oil shale. J Therm Anal Calorim. 2015;119:643–9.

Shao JA, Yan R, Chen HP, Wang BW, Lee DH, Liang DT. Pyrolysis characteristics and kinetics of sewage sludge by thermogravimetry Fourier transform infrared analysis. Energy Fuel. 2008;22:38–45.

Williams PT, Ahmad N. Investigation of oil-shale pyrolysis processing conditions using thermogravimetric analysis. Appl Energy. 2002;66(2):113–33.

Doğan ÖM, Uysal BZ. Non-isothermal pyrolysis kinetics of three Turkish oil shales. Fuel. 1996;75(12):1424–8.

Zhang Q, Li QF, Zhang LX, Fang YT, Wang ZQ. Experimental and kinetic investigation of pyrolysis, combustion, and gasification of deoiled asphalt. J Therm Anal Calorim. 2014;115:1929–38.

Al-Ayed OS, Matouq M, Anbar Z, Khaleel AM, Abu-Nameh E. Oil shale pyrolysis kinetics and variable activation energy principle. Appl Energy. 2010;87(4):1269–72.

Gersten J, Fainberg V, Hetsroni G, Shindler Y. Kinetic study of the thermal decomposition of polypropylene, oil shale, and their mixture. Fuel. 2000;79(13):1679–86.

Weitkamp AW, Gutberlet LC. Application of a microretort to problems in shale pyrolysis. Ind Eng Chem Process Des Dev. 1970;9(3):386–95.

Johannes I, Tiikma L, Zaidentsal A, Luik L. Kinetics of kukersite low-temperature pyrolysis in autoclaves. J Anal Appl Pyrol. 2009;85(1):508–13.

Thakur DS, Nuttall HE. Kinetics of pyrolysis of Moroccan oil shale by thermogravimetry. Ind Eng Chem Res. 1987;26(7):1351–6.

Aboulkas A, Harfi KE, Bouadili AE. Kinetic and mechanism of Tarfaya (Morocco) oil shale and LDPE mixture pyrolysis. J Mater Process Technol. 2008;206(1–3):16–24.

Lin LX, Lai DG, Guo EW, Zhan C, Xu GW. Oil shale pyrolysis in indirectly heated fixed bed with metallic plates of heating enhancement. Fuel. 2016;163:48–55.

Williams PT, Ahmad N. Influence of process conditions on the pyrolysis of Pakistani oil shales. Fuel. 1999;78(6):653–62.

Nazzal JM. The influence of grain size on the products yield and shale oil composition from the pyrolysis of Sultani oil shale. Energy Convers Manag. 2008;49(11):3278–86.

Dung NV. Factors affecting product yields and oil quality during retorting of Stuart oil shale with recycled shale: a screening study. Fuel. 1995;74(4):623–7.

Wang S, Jiang XM, Han XX, Tong JH. Effect of retorting temperature on product yield and characteristics of non-condensable gases and shale oil obtained by retorting Huadian oil shales. Fuel Process Technol. 2014;121(1):9–15.

Jaber JO, Probert SD, Williams PT. Evaluation of oil yield from Jordanian oil shales. Energy. 1999;24(9):761–81.

Kök MV, Pamir MR. Comparative pyrolysis and combustion kinetics of oil shale. J Anal Appl Pyrol. 2000;55(2):185–94.

Do DD. Modelling of oil shale pyrolysis in a fluid-bed retort. Fuel Process Technol. 1985;10(1):57–76.

Dung NV, Duffy GJ, Charlton BG. Comparison between model predictions and performance of process development units for oil shale processing. Fuel. 1990;69(9):1158–63.

Dung NV, Yip V. Basis of reactor design for retorting Australian oil shales. Fuel. 1991;70(11):1336–41.

Jiang XM, Han XX, Cui ZG. Mechanism and mathematical model of Huadian oil shale pyrolysis. J Them Anal Calorim. 2006;86(2):457–62.

Diaz JC, Braun RL. Process simulation model for a staged, fluidized-bed oil-shale retort with lift-pipe combustor. Lawrence Livemore Nat.Lab. [Rep.] UCRL-53517; 1984.

Camp DW, Braun RL, Diaz JC. Results of mathematical modeling of an oil shale retort having a fluidized-bed pyrolyzer and a lift-pipe combust. Fuel Process Technol. 1989;21(2):135–63.

Dung NV, Benito RG. Modelling of oil shale retorting block using ASPEN process simulator. Fuel. 1990;69(9):1113–8.

Han XX, Niu MT, Jiang XM. Combined fluidized bed retorting and circulating fluidized bed combustion system of oil shale: 2. Energy and economic analysis. Energy. 2014;74(2):788–94.

Wang S, Jiang XM, Han XX, Tong JH. Investigation of Chinese oil shale resources comprehensive utilization performance. Energy. 2012;42(1):224–32.

Yan R, Yang HP, Chin T, Liang DT, Chen HP, Zheng CG. Influence of temperature on the distribution of gaseous products from pyrolyzing palm oil wastes. Combust Flame. 2005;142(1–2):24–32.

Li X, Grace JR, Watkinson AP, Lim CJ, Ergüdenler A. Equilibrium modeling of gasification: a free energy minimization approach and its application to a circulating fluidized bed coal gasifier. Fuel. 2001;80:195–207.

Baumlin S, Broust F, Ferrer M, Meunier N, Marty E, Lédé J. The continuous self stirred tank reactor: measurement of the cracking kinetics of biomass pyrolysis vapours. Chem Eng Sci. 2005;60:41–55.

Lee DH, Yang HP, Yan R, Liang DT. Prediction of gaseous products from biomass pyrolysis through combined kinetic and thermodynamic simulations. Fuel. 2007;86(3):410–7.

Roine A. HSC chemistry 6.0 user’s guide. Pori: Outokumpu Research Oy; 2006.

Ballice L. Effect of demineralization on yield and composition of the volatile products evolved from temperature-programmed pyrolysis of Beypazari (Turkey) oil shale. Fuel Process Technol. 2005;86(6):673–90.

Hester NE, Mester ZC, Wang YG. Off gas emissions from simulated modified-in-situ oil shale retorting. Environ Sci Technol. 1983;17(12):714–77.

Sklarew DS, Hayes DJ, Petersen MR, Olsen KB, Pearson CD. Trace sulfur-containing species in the off gas from two oil shale retorting processes. Environ Sci Technol. 1984;18(8):592–600.

Sklarew DS, Hayes DJ. Trace nitrogen-containing species in the offgas from two oil shale retorting processes. Environ Sci Technol. 1984;18(8):600–3.

Tiwari P, Deo M. Compositional and kinetic analysis of oil shale pyrolysis using TGA–MS. Fuel. 2012;94(5):333–41.

Wang S, Song LZ, Jiang XM. Catalytic effects of Fe- and Ca-based additives on gas evolution during pyrolysis of Dachengzi oil shale of China. Oil Shale. 2018;35(1):39–55.

Campbell JH, Gallegos G, Gregg M. Gas evolution during oil shale pyrolysis. 2. Kinetic and stoichiometric analysis. Fuel. 1980;59(10):727–32.

Artok L, Schobert HH. Reaction of carboxylic acids under coal liquefaction conditions. 2: under hydrogen atmosphere. J Anal Appl Pyrol. 2000;54(1–2):235–46.

Huss EB, Burnham AK. Gas evolution during pyrolysis of various Colorado oil shales. Fuel. 1982;61(12):1188–96.

Campbell JH, Koskinas GJ, Gallegos G, Gregg M. Gas evolution during oil shale pyrolysis. 1. Nonisothermal rate measurements. Fuel. 1980;59(10):718–26.

Acknowledgements

The authors express their gratitude to the State Key Laboratory of Heavy Oil Processing of China University of Petroleum for shale oil samples analysis and technical advice. This work was supported by the National Natural Science Foundation of China (Grant Nos. 50906051 and 51704194), Young Teacher Training Scheme of Shanghai Universities (Grant No. ZZGCD15062) and the Research Star-up Fund from Shanghai University of Engineering Science (Grant No. 2015-52).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, S., Song, L. & Jiang, X. Prediction of gaseous products from Dachengzi oil shale pyrolysis through combined kinetic and thermodynamic simulations. J Therm Anal Calorim 134, 1129–1144 (2018). https://doi.org/10.1007/s10973-018-7501-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7501-7