Abstract

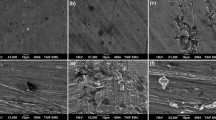

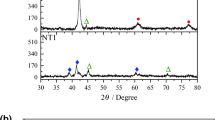

The nearly equiatomic Ni–Ti alloy (Nitinol) has been widely employed in the medical and dental fields owing to its shape memory or superelastic properties. The main concern about the use of this alloy derives form the fact that it contains a large amount of nickel (55% by mass), which is suspected responsible for allergic, toxic and carcinogenic reactions. In this work, the in vitro corrosion behavior of two Ti–Nb–Sn shape memory alloys, Ti–16Nb–5Sn and Ti–18Nb–4Sn (mass%) has been investigated and compared with that of Nitinol. The in vitro corrosion resistance was assessed in naturally aerated Ringer’s physiological solution at 37°C by corrosion potential and electrochemical impedance spectroscopy (EIS) measurements as a function of exposure time, and potentiodynamic polarization curves. Corrosion potential values indicated that both Ni–Ti and Ti–Nb–Sn alloys undergo spontaneous passivation due to spontaneously formed oxide film passivating the metallic surface, in the aggressive environment. It also indicated that the tendency for the formation of a spontaneous oxide is greater for the Ti–18Nb–5Sn alloy. Significantly low anodic current density values were obtained from the polarization curves, indicating a typical passive behaviour for all investigated alloys, but Nitinol exhibited breakdown of passivity at potentials above approximately 450 mV(SCE), suggesting lower corrosion protection characteristics of its oxide film compared to the Ti–Nb–Sn alloys. EIS studies showed high impedance values for all samples, increasing with exposure time, indicating an improvement in corrosion resistance of the spontaneous oxide film. The obtained EIS spectra were analyzed using an equivalent electrical circuit representing a duplex structure oxide film, composed by an outer and porous layer (low resistance), and an inner barrier layer (high resistance) mainly responsible for the alloys corrosion resistance. The resistance of passive film present on the metals’ surface increases with exposure time displaying the highest values to Ti–18Nb–4Sn alloy. All these electrochemical results suggest that Ti–Nb–Sn alloys are promising materials for biomedical applications.

Similar content being viewed by others

References

Buehler WJ, Wang FE. A summary of recent research on the nitinol alloys and their potential application in ocean engineering. Ocean Eng. 1968;1:105.

Andrasen GA. A clinical trial of alignment of teeth using a 0.019 inch thermal nitinol wire with a transition temperature range between 31°C and 45°C. Am J Orthod. 1980;78:528.

Barras CDJ. Nitinol—its use in vascular surgery and other applications. Eur J Vasc Endovasc Surg. 2000;19:564.

Shabolovskaya SA. Physicochemical and biological aspects of nitinol as a biomaterial. Int Mater Rev. 2001;46:233.

Shabolovskaya SA. Surface, corrosion and biocompatibility aspects of nitinol as an implant material. Biomed Med Eng. 2002;12:69.

Castelman LS, Motzkin SM. Biocompatibility of clinical implant materials. Boca Raton: CRC Press; 1981.

Black J. Biological performance of materials. New York: Fundamentals of biocompatibility. Marcel Dekker; 1992.

Remes A, Williams DF. Immune response in biocompatibility. Biomaterials. 1992;13:731.

Bass JK, Fine H, Cisnero GJ. Nickel hypersensitivity in the orthodontic patient. Am J Dentofacial Orthop. 1993;103:280.

Cramers M, Lucht L. Metal sensitivity in patients treated for tibial fractures with plates of stainless steel. Acta Orthop Scand. 1977;48:245.

Koster R, Vieluf D, Kiehn M, Sommerauer M, Kä J, Meinertz T, Hamm CW. Coronary angioplasty in octogenarians. quality of life and costs. Eur Heart J. 1999;20:605.

Wataha JC, Lockwood PE, Marek M, Ghazi M. Ability of Ni-containing biomedical alloys to activate monocytes and endothelial cells in vitro. J Biomed Mater Res. 1999;45:251.

Steinemann SG. Surface performance of titanium. Warrendale: TMS; 1996. p. 33.

Takahashi E, Sakurai T, Watanabe S, Masahashi N, Hanada S. Effect of heat treatment and Sn content on superelasticity in biocompatible TiNbSn alloys. Mater Trans. 2002;43:2978.

Ozaki T, Matsumoto H, Watanabe S, Hanada S. Beta ti alloys with low Young’s modulus. Mater Trans. 2004;45:2776.

Matsumoto H, Watanabe S, Hanada S. Beta TiNbSn alloys with low Young’s modulus and high strength. Mater Trans. 2005;46:1070.

Matsumoto H, Watanabe S, Hanada S. Microstructures and mechanical properties of metastable β TiNbSn alloys cold rolled and heat treated. J Alloys Compd. 2007;439:146.

Jung TK, Abumiya T, Masahashi N, Kim MS, Hanada S. Fabrication of a high performance Ti alloy implant for an artificial hip joint. Mater Sci Forum. 2009;620–622:591.

Kim JI, Kim HY, Inamura T, Hosoda H, Miyazaki S. Shape memory characteristics of Ti–22Nb–(2–8)Zr(at.%) biomedical alloys. Mater Sci Eng. 2005;A 403:334.

Abdel-Hady M, Henoshita K, Morinaga M. General approach to phase stability and elastic properties of β-type Ti-alloys using electronic parameters. Scripta Mater. 2006;55:477.

Kim HY, Satoru H, Kim JI, Hosoda H, Miyazaki S. Mechanical properties and shape memory behavior of Ti–Nb alloys. Mater Trans. 2004;45:2443.

Takahashi E, Sakurai T, Watanabe S, Masahashi N, Hanada S. Effect of heat treatment and Sn content on superelasticity in biocompatible TiNbSn alloys. Mater Trans. 2002;44:2978.

Hao YL, Li SJ, Sun SY, Yang R. Effect of Zr and Sn on Young’s modulus and superelasticity of Ti–Nb-based alloys. Mater Sci Eng. 2006;A 441:112.

Wang BL, Zheng YF, Zhao LC. Effects of Sn content on the microstructure, phase constitution and shape memory effect of Ti–Nb–Sn alloys. Mater Sci Eng. 2008;A 486:146.

Kim JI, Kim HY, Inamura T, Hosoda H, Miyazaki S. Effect of annealing temperature on microstructure and shape memory characteristics of Ti–22Nb–6Zr(at.%) biomedical alloy. Mater Trans. 2006;47:505.

Hao YL, Li SJ, Sun SY, Zheng CY, Hu QM, Yang R. Super-elastic titanium alloy with unstable plastic deformation. Appl Phys Lett. 2005;87:091906.

Zheng YF, Wang BL, Wang JG, Li C, Zhao LC. Corrosion behaviour of Ti–Nb–Sn shape memory alloys in different simulated body solutions. Mater Sci Eng. 2006;A 438–440:891.

Cremasco A, Osorio WR, Freire CMA, Garcia A, Caram R. Electrochemical corrosion behaviour of a Ti–35Nb alloy for medical prostheses. Electrochim Acta. 2008;53:4867.

Gonzalez JEG, Mirza-Rosca JC. Study of the corrosion behaviour of titanium and some of its alloys for biomedical and dental applications. J Electroanal Chem. 1999;471:109.

Oliveira NTC, Biaggio SR, Rocha-Filho RC, Bocchi N. Electrochemical studies on zirconium and its compatible alloys Ti–50Zr at.% and Zr–2.5Nb wt% in simulated physiologic media. J Biomed Mater Res. 2005;39:397.

Shukla AK, Balasubramaniam R. Effect of surface treatment on electrochemical behaviour of CP Ti, Ti–6Al–4 V and Ti–13Nb–13Zr alloys in simulated human body fluid. Corros Sci. 2006;48:1696.

Cai Z, Shafer T, Watanabe I, Nunn ME, Okabe T. Electrochemical characterization of cast titanium alloys. Biomaterials. 2003;24:213.

Kobaysci E, Wang TJ, Doi H, Yoneyama T, Hamanaka H. Mechanical properties and corrosion resistance of Ti–6Al–7Nb alloy dental castings. J Mater Sci Mater Med. 1998;9:567.

Yu SY, Scully JR. Corrosion and passivity of Ti-13% Nb-13% Zr in comparison to other biomedical implant alloys. Corrosion. 1997;53:965.

Metikos-Hukovic M, Kwokal A, Piljac J. The influence of niobium and vanadium on passivity of titanium-based implants in physiological solution. Biomaterials. 2003;24:3765.

Barsukov E, Macdonald JR. Impedance Spectroscopy. 2nd ed. New York: Wiley; 2005.

Osorio WR, Spinelli JE, Ferriera IL, Garcia A. The roles of macrosegregation and of dendritic array spacings on the electrochemical behavior of an Al-4.5 wt% Cu alloy. Electrochim Acta. 2007;52:3265.

Assis SL, Wolynec S, Costa I. Corrosion characterization of titanium alloys by electrochemical techniques. Electrochim Acta. 2006;51:1815.

Pan J, Thierry D, Leygraf C. Electrochemical impedance spectroscopy study of the passive oxide film on titanium for implant application. Electrochim Acta. 1996;41:1143.

Aziz-Kerzo M, Conroy KG, Fenelon AM, Farell ST, Breslin CB. Electrochemical studies on the stability and corrosion resistance of titanium-based implant materials. Biomaterials. 2001;22:1531.

Moffat DL, Larbalestier DC. Competition between martensite and omega in quenched Ti–Sn–Nb alloys. Metall Trans. 1988;19A:1687.

Gudic S, Radosevic J, Kliskic M. Study of passivation of Al and Al–Sn alloys in borate buffer solutions using electrochemical impedance spectroscopy. Electrochim Acta. 2002;47:3009.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rosalbino, F., Macciò, D., Scavino, G. et al. In vitro corrosion behaviour of Ti–Nb–Sn shape memory alloys in Ringer’s physiological solution. J Mater Sci: Mater Med 23, 865–871 (2012). https://doi.org/10.1007/s10856-012-4560-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-012-4560-3