Abstract

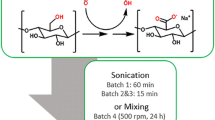

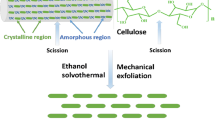

In an attempt to prepare cellulose nanocrystals (CNCs) by TEMPO-mediated oxidation of microcrystalline cellulose (MCC), a new species of MCC called AaltoCell was placed under scrutiny. Unlike Avicel, AaltoCell is a never-dried species, still containing ca. 10% xylan in its structure. According to thermoporosimetry, the pore size distributions of AaltoCell and Avicel did not differ from each other but after TEMPO-oxidation, AaltoCell exhibited a far lower degree of porosity, hypothetically ascribed to its hemicellulose content. Surprisingly, the charge density imposed by TEMPO-oxidation did not vary between AaltoCell and Avicel despite the different microfibril widths observed, respectively. After TEMPO-oxidation and centrifugation the fine fraction share, indicating the CNC yield, was not more than 11% for AaltoCell, compared to 20% from Avicel.

Similar content being viewed by others

References

Aarne N, Kontturi E, Laine J (2012) Influence of adsorbed polyelectrolytes on pore size distribution of a water-swollen biomaterial. Soft Matter 8:4740–4749. doi:10.1039/c2sm07268h

Araki J, Wada M, Kuga S, Okano T (1999) Influence of surface charge on viscosity behavior of cellulose microcrystal suspension. J Wood Sci 45:258–261. doi:10.1007/BF01177736

Beck-Candanedo S, Roman M, Gray DG (2005) Effect of reaction conditions on the properties and behavior of wood cellulose nanocrystal suspensions. Biomacromolecules 6:1048–1054. doi:10.1021/bm049300p

Dahl O, Vanhatalo K, Parviainen K (2011a) A novel method to produce microcellulose. WO patent application WO2011/154600 A2

Dahl O, Vanhatalo K, Parviainen K, Svedman M (2011b) A novel method to produce microcellulose. WO patent application WO 2011/154601 A1

Donaldson L (2007) Cellulose microfibril aggregates and their size variation with cell wall type. Wood Sci Technol 41:443. doi:10.1007/s00226-006-0121-6

Edgar CD, Gray DG (2003) Smooth model cellulose I surfaces from nanocrystal suspensions. Cellulose 10:299–306. doi:10.1023/A:1027333928715

Elazzouzi-Hafraoui S, Nishiyama Y, Putaux J, Heux L, Dubreuil F, Rochas C (2008) The shape and size distribution of crystalline nanoparticles prepared by acid hydrolysis of native cellulose. Biomacromolecules 9:57–65. doi:10.1021/bm700769p

Fernandes AN, Thomas LH, Altaner CM, Callow P, Forsyth VT, Apperley DC, Kennedy CJ, Jarvis MC (2011) Nanostructure of cellulose microfibrils in spruce wood. Proc Natl Acad Sci USA 108:E1195–E1203. doi:10.1073/pnas.1108942108

Habibi Y, Lucia LA, Rojas O (2010) Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem Rev 110:3479–3500. doi:10.1021/cr900339

Hu TQ, Hashaikeh R, Berry R (2014) Isolation of a novel, crystalline cellulose material from the spent liquor of cellulose nanocrystals (CNCs). Cellulose 21:3217–3229. doi:10.1007/s10570-014-0350-z

Huang YY, Terentjev EM (2012) Dispersion of carbon nanotubes: mixing, sonication, stabilization, and composite properties. Polymers 4:275–295. doi:10.3390/polym4010275

Huang YY, Knowles TPJ, Terentjev EM (2009) Strength of nanotubes, filaments, and nanowires from sonication-induced scission. Adv Mater 21:3945–3948. doi:10.1002/adma.200900498

Hubbe MA, Venditti RA, Rojas OJ (2007) What happens to cellulosic fibers during papermaking and recycling? A review. BioResources 2:739–788. doi:10.15376/biores.2.4.739-788

Isogai A, Saito T, Fukuzumi H (2011) TEMPO-oxidized cellulose nanofibers. Nanoscale 3:71–85. doi:10.1039/C0NR00583E

Kontturi E, Meriluoto A, Penttilä PA, Baccile N, Malho J, Potthast A, Rosenau T, Ruokolainen J, Serimaa R, Laine J, Sixta H (2016) Degradation and crystallization of cellulose in hydrogen chloride vapor for high-yield isolation of cellulose nanocrystals. Angew Chem Int Ed 55:14455–14458. doi:10.1002/anie.201606626

Lorenz M, Sattler S, Reza M, Bismarck A, Kontturi E (2017) Cellulose nanocrystals by acid vapour: towards more effortless isolation 1 of cellulose nanocrystals. Faraday Discuss. doi:10.1039/c7fd00053g

Lu Q, Cai Z, Lin F, Tang L, Wang S, Huang B (2016) Extraction of cellulose nanocrystals with high yield of 88% by simultaneous mechanochemical activation and phosphotungstic acid hydrolysis. ACS Sustain Chem Eng 4:2165–2172. doi:10.1021/acssuschemeng.5b01620

Maloney TC (2015) Thermoporosimetry of hard (silica) and soft (cellulosic) materials by isothermal step melting. J Therm Anal Calorim 121:7–17. doi:10.1007/s10973-015-4592-2

Maloney TC, Paulapuro H (2001) Thermoporosimetry of pulp fibers. In: Science papermaking, transactions of the 12th fundamental research symposium, vol 2, pp 897–926

Oehme DP, Doblin MS, Wagner J, Bacic A, Downton MT, Gidley MJ (2015) Gaining insight into cell wall cellulose macrofibril organisation by simulating microfibril adsorption. Cellulose 22:3501–3520. doi:10.1007/s10570-015-0778-9

Okita Y, Saito T, Isogai A (2010) Entire surface oxidation of various cellulose microfibrils by TEMPO-mediated oxidation. Biomacromolecules 11:1696–1700. doi:10.1021/bm100214b

Peyre J, Pääkkönen T, Reza M, Kontturi E (2015) Simultaneous preparation of cellulose nanocrystals and micron-sized porous colloidal particles of cellulose by TEMPO-mediated oxidation. Green Chem 17:808–811. doi:10.1039/c4gc02001d

Pönni R, Vuorinen T, Kontturi E (2012) Proposed nano-scale coalescence of cellulose in chemical pulp fibers during technical treatments. BioResources 7:6077–6108. doi:10.15376/biores.7.4.6077-6108

Sacui IA, Nieuwendaal RC, Burnett DJ, Stranick SJ, Jorfi M, Weder C, Foster EJ, Olsson RT, Gilman JW (2014) Comparison of the properties of cellulose nanocrystals and cellulose nanofibrils isolated from bacteria, tunicate, and wood processed using acid, enzymatic, mechanical, and oxidative methods. ACS Appl Mater Interfaces 6:6127–6138. doi:10.1021/am500359f

Saito T, Isogai A (2004) TEMPO-mediated oxidation of native cellulose. The effect of oxidation conditions on chemical and crystal structures of the water-insoluble fractions. Biomacromolecules 5:1983–1989. doi:10.1021/bm0497769

Saito T, Kimura S, Nishiyama Y, Isogai A (2007) Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 8:2485–2491. doi:10.1021/bm0703970

Saito T, Hirota M, Tamura N, Kimura S, Fukuzumi H, Heux L, Isogai A (2009) Individualization of nano-sized plant cellulose fibrils by direct surface carboxylation using TEMPO catalyst under neutral conditions. Biomacromolecules 10:1992–1996. doi:10.1021/bm900414t

Saito T, Kuramae R, Wohlert J, Berglund LA, Isogai A (2012) An ultrastrong nanofibrillar biomaterial: the strength of sigle cellulose nanofibrils revealed via sonication-induced fragmentation. Biomacromolecules 14:248–253. doi:10.1021/bm301674e

Salminen R, Reza M, Pääkkönen T, Peyre J, Kontturi E (2017) TEMPO-mediated oxidation of microcrystalline cellulose: limiting factors for cellulose nanocrystal yield. Cellulose 24:1657–1667. doi:10.1007/s10570-017-1228-7

Yu H, Qin Z, Liang B, Liu N, Zhou Z, Chen L (2013) Facile extraction of thermally stable cellulose nanocrystals with high yield of 93% through hydrochloric acid hydrolysis under hydrothermal conditions. J Mater Chem A 1:3938–3944. doi:10.1039/C3TA01150J

Acknowledgments

We acknowledge Academy of Finland (259500) for financial support, and would kindly acknowledge Moriam Most and Leena Nolvi for helping with the thermoporosity measurements and calculations, and Jenna Järvenpää and Professor Olli Dahl, the inventor of AaltoCell-process for providing the AaltoCell, with the DP determinations and hemicellulose analysis.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Salminen, R., Reza, M., Vanhatalo, K. et al. Influence of the quality of microcrystalline cellulose on the outcome of TEMPO-mediated oxidation. Cellulose 24, 5697–5704 (2017). https://doi.org/10.1007/s10570-017-1531-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-017-1531-3