Abstract

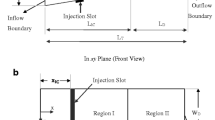

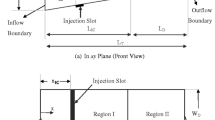

In resin injection pultrusion, the liquid resin is injected through the injection slots into the fiber reinforcement; the liquid resin penetrates through the fibers as well as pushes the fibers towards the centerplane causing fiber compaction. The compacted fibers are more difficult to penetrate, thus higher resin injection pressure becomes necessary to achieve complete reinforcement wetout. Lower injection pressures below a certain range (depending upon the fiber volume fraction and resin viscosity) cannot effectively penetrate through the fiber bed and thus cannot achieve complete wetout. Also, if the degree of compaction is very high the fibers might become essentially impenetrable. The more viscous the resin is, the harder it is to penetrate through the fibers and vice versa. The effect of resin viscosity on complete wetout achievement with reference to fiber-reinforcement compaction is presented in this study.

Similar content being viewed by others

References

Jeswani, A.L., Roux, J.A.: Numerical modeling of design parameters for manufacturing polyster/glass composites by resin injection pultrusion. Polym. Polym. Compos. 14, 651–669 (2006)

Liu, X.L.: A finite element/nodal volume technique for flow simulation of injection pultrusion. Compos. Part A 34, 649–661 (2003)

Liu, X.L.: Iterative and transient numerical models for flow simulation of injection pultrusion. Compos. Struct. 66, 175–180 (2004)

Lee, I.J., Young, W.B., Lin, R.J.: Mold filling and cure modeling of RTM and SRIM processes. Compos. Struct. 27, 109–120 (1993)

Kommu, S., Komanmi, B., Kardos, J.L.: Modeling of injection pultrusion processes: A numerical approach. Polymer Compos. 19, 335–346 (1998)

Voorakaranam, S., Joseph, B., Kardos, J.L.: Modeling and control of an injection pultrusion process. J. Compos. Mater. 33, 1173–1202 (1999)

Srinivasagupta, D., Kardos, J.L.: Rigorous dynamic model-based economic design of the injected pultrusion process with controllability considerations. J. Compos. Mater. 37, 1851–1888 (2003)

Srinivasaguta, D., Potaraju, S., Kardos, J.L., Joseph, B.: Steady state and dynamic analysis of a bench-scale injected pultrusion process. Compos. A: Appl. Sci. Manuf. 34, 835–846 (2003)

Mustafa, I., Khomami, B., Kardos, J.L.: 3-D nonisothermal flow simulation model for injected pultrusion processes. AICHE J. 45, 151–163 (1999)

Rahatekar, S.S., Roux, J.A.: Numerical simulation of pressure variation and resin flow in injection pultrusion. J. Compos. Mater. 37, 1067–1082 (2003)

Ranga, B.K., Roux, J.A., Jeswani, A.L.: Effect of chamber length and pull speed of tapered resin injection pultrusion. J. Reinf. Plast. Compos. 30, 1373–1387 (2011)

Mitlapalli, R., Roux, J.A., Jeswani, A.L.: Chamber length and injection slot location and multiple slots of tapered resin injection pultrusion. J. Porous Media 14, 17–32 (2011)

Palikhel, D.R., Roux, J.A., Jeswani, A.L.: Die-attached versus die detached resin injection chamber for pultrusion. J. Appl. Compos. Mater. 20, 55–72 (2013)

Ranjit, S.: Impact of Design Parameters on Detached-Die Tapered Resin Injection Pultrusion. Masters Thesis, University of Mississippi (2012)

Gutowski, T.G., Cai, Z., Kingery, J., Wineman, S.J.: Resin flow/fiber deformation experiments. SAMPE Q. 17, 54–58 (1986)

Gutowski, T.G., Cai, Z., Boucher, D., Kingery, J., Wineman, S.: Consolidation experiments for laminate composites. J. Compos. Mater. 21, 650–669 (1987)

Gutowski, T.G., Morigaki, T., Cai, Z.: Consolidation experiments for laminate composites. J. Compos. Mater. 21, 172–188 (1987)

Batch, G.L., Cumiskey, S., Macosko, C.W.: Compaction of fiber reinforcements. Polymer Compos. 23, 307–318 (2002)

Ding, Z., Li, S., Yang, H., Lee, L.J.: Numerical and experimental analysis of resin flow and cure in resin injection pultrusion (RIP). Polym. Compos. 21, 762–778 (2000)

Kim, Y.R., McCarthy, S.P.: Compressibility and relaxation of fiber reinforcements during composite processing. Polymer Compos. 12, 13–19 (1991)

Kim, Y.R., McCarthy, S.P., Fanucci, J.P., Nolet, S.C., Koppernaes, C.: Resin flow through fiber reinforcement during composite processing. SAMPE Q. 22, 16–22 (1991)

Carman, P.C.: Fluid flow through granular beds. Trans. Int. Chem. Eng. 15, 150–166 (1937)

Patankar, S.: Numerical Heat and Fluid Flow. Hemisphere Publishing Corporation, New York (1980)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shakya, N., Roux, J.A. & Jeswani, A.L. Effect of Resin Viscosity in Fiber Reinforcement Compaction in Resin Injection Pultrusion Process. Appl Compos Mater 20, 1173–1193 (2013). https://doi.org/10.1007/s10443-013-9320-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10443-013-9320-0