Abstract

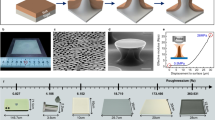

Components with surface nanostructures suitable for biomimetic dry adhesion have a great potential in applications such as gecko tape, climbing robots, and skin patches. In this study, a nanosphere lithography technique with self-assembly nanospheres was developed to achieve effective and efficient fabrication of dry-adhesion structures. Self-assembled monolayer nanospheres with high regularity were obtained through tilted dip-coating. Reactive-ion etching of the self-assembled nanospheres was used to fabricate nanostructures of different shapes and aspect ratios by varying the etching time. Thereafter, nickel molds with inverse nanostructures were replicated using the electroforming process. Polydimethylsiloxane (PDMS) nanostructures were fabricated through a gas-assisted hot-embossing method. The pulling test was performed to measure the shear adhesion on the glass substrate of a sample, and the static contact angle was measured to verify the hydrophobic property of the structure. The enhancement of the structure indicates that the adhesion force increased from 1.2 to 4.05 N/cm2 and the contact angle increased from 118.6° to 135.2°. This columnar structure can effectively enhance the adhesion ability of PDMS, demonstrating the potential of using nanosphere lithography for the fabrication of adhesive structures.

Similar content being viewed by others

References

E. Arzt, S. Gorb, R. Spolenak, Proc. Natl. Acad. Sci. 100, 10603 (2003)

K. Autumn, A.M. Peattie, Integr. Comp. Biol. 42, 1081 (2002)

K. Autumn, J. Exp. Biol. 209, 3558 (2006)

M. Xu, F. Du, S. Ganguli, A. Roy, L. Dai, Nat. Commun. 7, (2016)

O.J. Chaudhary, E.P. Calius, J.V. Kennedy, M. Dickinson, T. Loho, J. Travas-Sejdic, Eur. Polym. J. 84, 13 (2016)

Y. Cho, G. Kim, Y. Cho, S.Y. Lee, H. Minsky, K.T. Turner, D.S. Gianola, S. Yang, Adv. Mater. 27, 7788 (2015)

L. Ge, S. Sethi, L. Ci, P.M. Ajayan, A. Dhinojwala, Proc. Natl. Acad. Sci. 104, 10792 (2007)

J. Lee, R.S. Fearing, K. Komvopoulos, Appl. Phys. Lett. 93, 191910 (2008)

M.L.B. Palacio, B. Bhushan, S.R. Schricker, Mater. Lett. 92, 409 (2013)

M.K. Choi, H. Yoon, K. Lee, K. Shin, Langmuir. 27, 2132 (2011)

D. Xia, S.R.J. Brueck, Nano Lett. 4, 1295 (2004)

B.G. Prevo, O.D. Velev, Langmuir. 20, 2099 (2004)

D. Nagao, R. Kameyama, H. Matsumoto, Y. Kobayashi, M. Konno, Colloids Surf. Physicochem. Eng. Asp. 317, 722 (2008)

T.J. Wang, K.C. Hsu, Y.C. Liu, C.H. Lai, H.P. Chiang, J. Opt. 18, 055006 (2016)

Y.K. Su, J.J. Chen, C.L. Lin, S.M. Chen, W.L. Li, C.C. Kao, Jpn. J. Appl. Phys. 47, 6706 (2008)

L. Ji, Y.F. Chang, B. Fowler, Y.C. Chen, T.M. Tsai, K.C. Chang, M.C. Chen, T.C. Chang, S.M. Sze, E.T. Yu, J.C. Lee, Nano Lett. 14, 813 (2014)

J.Y. Shiu, C.W. Kuo, P. Chen, C.Y. Mou, Chem. Mater. 16, 561 (2004)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service, and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled.

Electronic supplementary material

Below is the link to the electronic supplementary material.

339_2018_1639_MOESM1_ESM.docx

SEM images of the column structure at a 45° tilted-view after etching for a 360 s; b 390 s; c 420 s; d 450 s (DOCX 183 KB)

Rights and permissions

About this article

Cite this article

Kuo, P.C., Chang, N.W., Suen, Y. et al. Fabrication of biomimetic dry-adhesion structures through nanosphere lithography. Appl. Phys. A 124, 236 (2018). https://doi.org/10.1007/s00339-018-1639-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-018-1639-9