Abstract

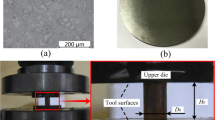

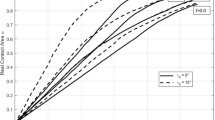

Due to the so-called “size effect,” the tribological theory for traditional plastic forming processes cannot be applied directly to the micro/meso forming processes. Therefore, the friction behavior in micro/meso forming was systematically studied in this paper. Firstly, based on the open-close lubrication pockets model, a scale factor was introduced to modify the Wanheim/Bay friction model and a micro/meso forming friction model was established. The established friction model can be used in the numerical simulation of micro/meso forming processes. Secondly, the simulation and experiment of cylindrical upsetting without lubricant were carried out. Then, by comparing the simulation and experiment results, the calculation method of friction factor in Wanheim/Bay friction model was proposed. Finally, the simulation and experiment of cylindrical upsetting under the condition of liquid lubrication were also performed, and thus an approach to calculate the size factor in the established friction model for micro/meso forming was proposed. The friction model built in this paper and the methods to calculate the parameters in this model are of great importance for the quantitative study of size effect in micro/meso forming processes.

Similar content being viewed by others

References

Tan X (2002) Comparisons of friction model in bulk metal forming. Tribol Int 35:385–393

Doege E, Kaminsky C, Bagaviev A (1999) A new concept for the description of surface friction phenomena. Mater Process Technol 94:189–192

Wanheim T (1973) Friction at high normal pressures. Wear 25:225–244

Bay N, Wanheim T (1976) Real area of contact and friction stress at high pressure sliding contact. Wear 38:201–209

Wanheim T, Bay N, Petersen AS (1974) A theoretically determined model for friction in metal working processes. Wear 28:251–258

Engel U, Eckstein R (2002) Microforming-from basic research to its realization. J Mater Process Technol 125-126:35–44

Han JJ, Zheng W, Wang GC, Yu MZ (2018) Experimental study on size effect of dry friction in meso/micro-upsetting process. Int J Adv Manuf Technol 95:1127–1133

Engel U (2006) Tribology in micro forming. Wear 260:265–273

Chan WL, Fu MW, Yang B (2012) Experimental studies of the size effect affected micro-scale plastic deformation in micro upsetting process. Mater Sci Eng A 534:374–383

Hong SK (2015) A quantitative study of tribological size effect in micro-forming with a multi-region FEA model. Tribol Int 90:104–112

Peng LF, Lai XM, Lee HJ (2010) Friction behavior modeling and analysis in micro/meso scale metal forming process. Mater Design 31:1953–1961

Wang CJ, Guo B, Shan DB, Zhang MM, Bai X (2014) Tribological behaviors in microforming considering microscopically trapped lubricant at contact interface. J Mater Process Technol 71:2083–2290

Nellemann T, Bay N, Wanheim T (1977) Real contact area and friction stress-the role of trapped lubricant. Wear 43:45–53

Bay N (1987) Friction stress and normal stress in bulk metal-forming processes. J Mech Work Technol 14(2):203–223

Zheng W (2013) Modeling and analysis of dry friction in micro-forming of metals. Tribology Tribol Int 57:202–209

Leu DK (2009) A simple dry friction model for metal forming process. J Mater Process Technol 209(5):2361–2368

Funding

This work was supported by the National Natural Science Foundation of China (Nos. 51505256, 51775311).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yan, W., Han, J., Zheng, W. et al. Establishment of friction model and calculation of size factor in micro/meso forming processes. Int J Adv Manuf Technol 98, 3061–3069 (2018). https://doi.org/10.1007/s00170-018-2441-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-018-2441-8